- ● Introduction

- ● Powder Testing Apparatus

True density, also referred to as absolute density, is a fundamental property of materials that quantifies the mass of the actual substance within a unit volume, excluding any open or closed pores. It serves as a key parameter for understanding the intrinsic characteristics of a material, closely related to its structure and composition. To measure true density, a gas pycnometer is commonly used, employing the gas displacement method based on Boyle's Law. This method is rapid, non-destructive, precise, applicable to various materials, and yields reproducible results, making it indispensable for material characterization and quality control across industries.

The tapped density can be determined by mechanically tapping a container producing a regular vibration that rearranges the powder particles, thus reducing the volume of the interparticle voids. Regularly conducting tapped density tests ensures that product quality aligns with standards and contributes to maintaining consistency and stability in product quality.

In practical applications, true density and tapped density are often used together to provide a more comprehensive understanding of the physical characteristics of powder samples. These parameters are frequently employed in powder engineering, pharmaceuticals, cosmetics, and food industries, among others, to evaluate powder quality, process control, and product performance.

Powder Testing Apparatus

BeDensi T Pro Series

Tapped Density Tester with a Wallet-Friendly Solution

Number of Workstations: 1-3

Tapping Speed: 100 - 300 taps/min

Repeatability: ≤1% variation

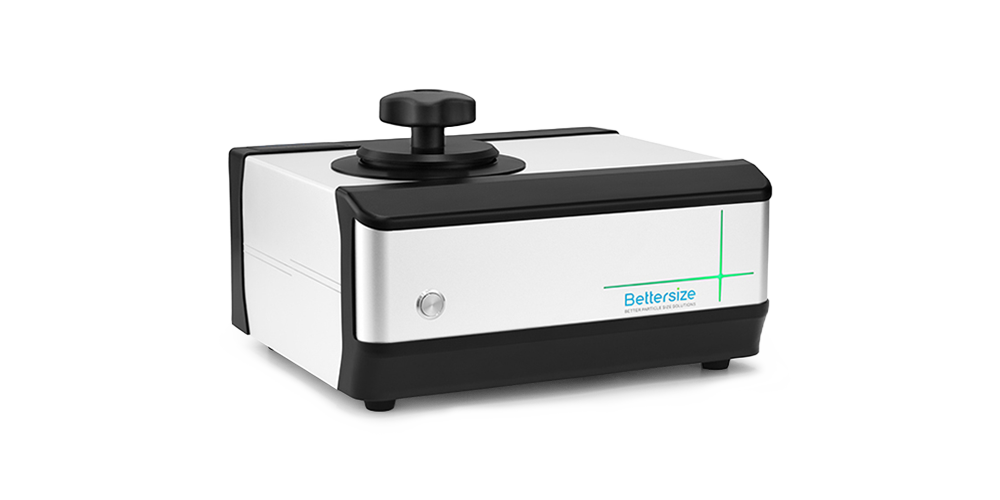

BetterPyc 380

Gas Pycnometer

Technology: Gas Displacement Method

Temperature Range: 10 - 65 ℃

Resolution: 0.0001 g/cm³