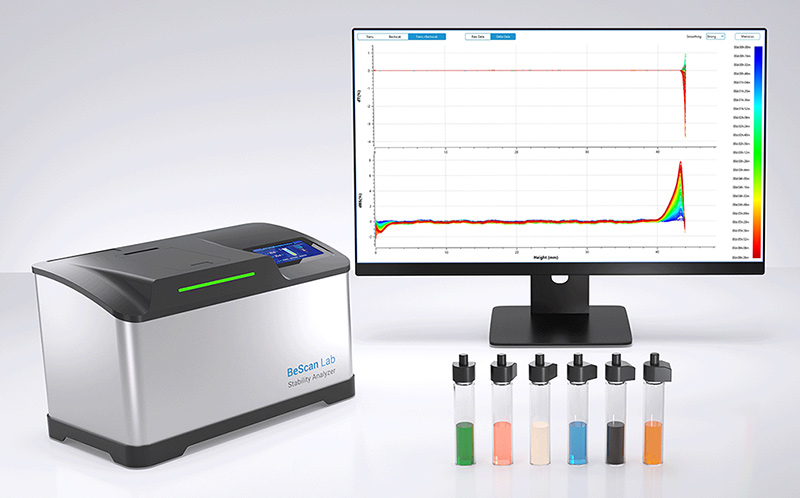

BeScan Lab

BeScan Lab, the versatile, sensitive, and reliable stability analyzer based on Static Multiple Light Scattering (SMLS) technology, is widely used in the formulation development and product quality control. It accommodates a wide range of sample concentrations up to 95% v/v and types such as emulsions, suspensions, and foams, with temperature scanning capabilities reaching up to 80 °C. BeScan Lab provides both qualitative analysis and quantification of destabilization, helping you monitor long-term product stability and achieve optimal shelf life.

Features and Benefits

- ● Real stability analysis for dispersions with volume fraction up to 95%

- ● Particle size measurement range from 0.01 to 1,000 μm

- ● Non-destructive stability analysis: Non-contact, non-dilution, non-shearing

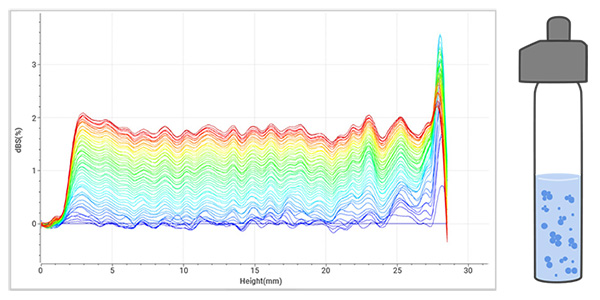

- ● 20 µm resolution data acquisition enables quicker sample stability observation than the naked eye

- ● Temperature control up to 80 °C to accelerate destabilization

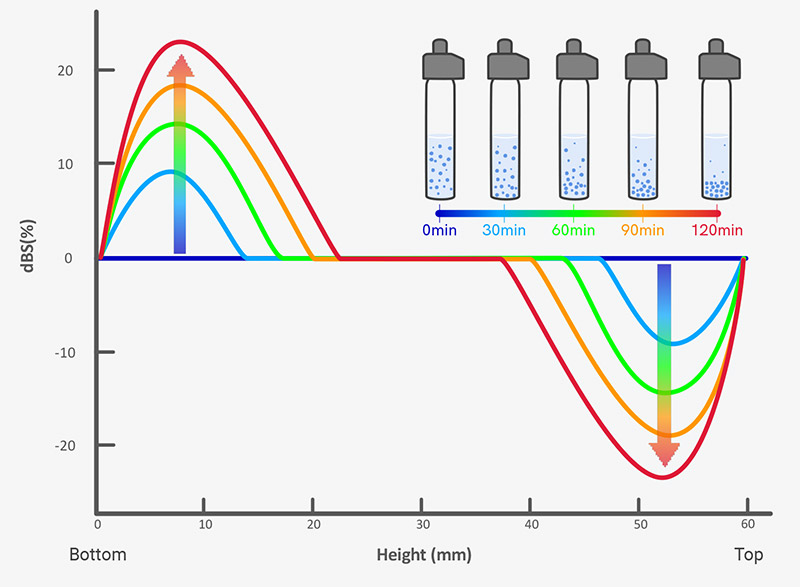

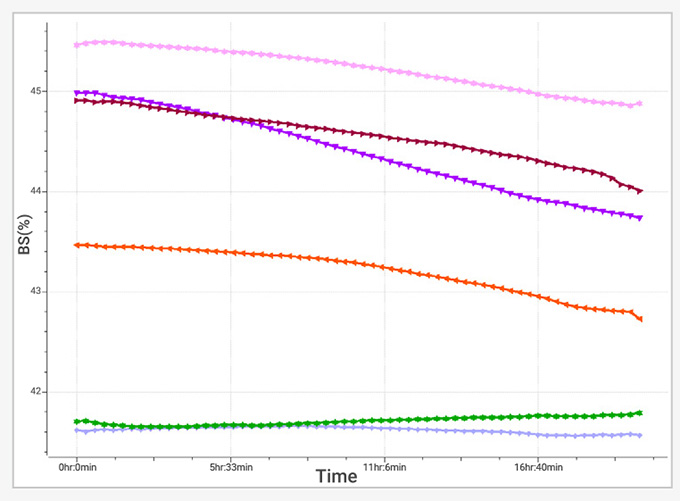

- ● Identification of various unstable phenomena: creaming, sedimentation, flocculation, coalescence, and phase separation

- ● Quantification of destabilizations and study of kinetics

Video

How to Operate BeScan Lab to Measure Stability?

BeScan Lab – Stability Excellence Within Reach

Fundamentals of BeScan Lab | Stability Analyzer

What is Dispersion Stability? How do We Measure It?

Overview of BeScan Lab | Stability Analyzer

Overview

Features

Technology

Software

Accessories

Specification

What BeScan Lab Provides?

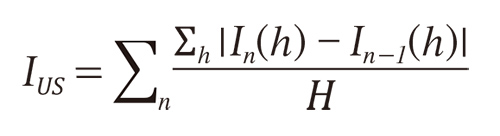

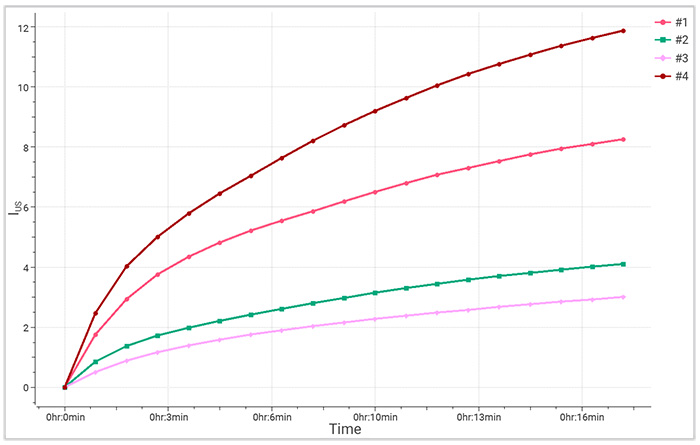

- lnstability index (lus)

- Mean particle size

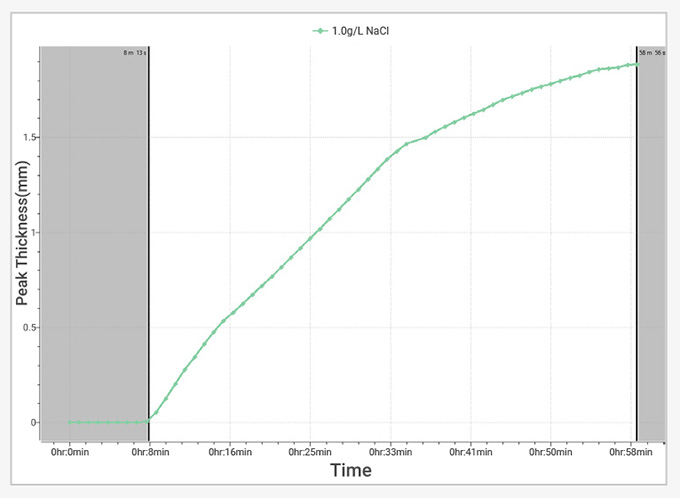

- Hydrodynamic analysis

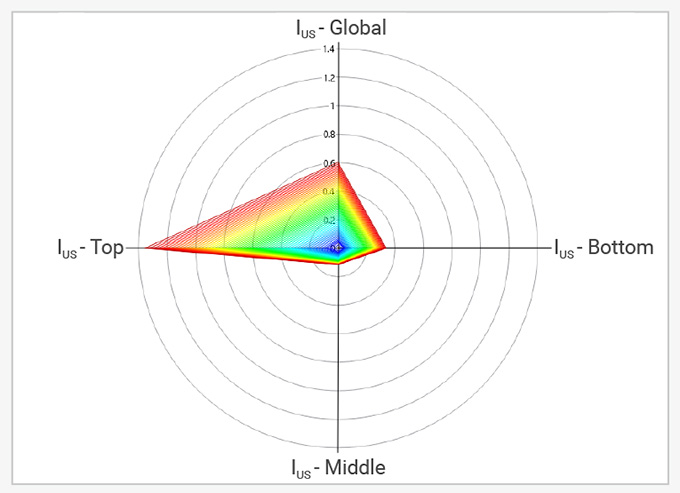

- Radar chart for regional lus

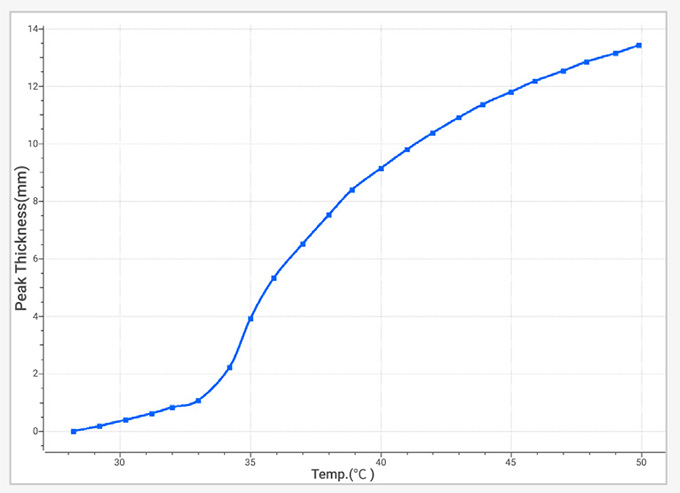

- Temperature trend testing

- Particle migration rate

Why You Need It?

From Raw Materials to Finish

BeScan Lab plays a crucial role throughout the product lifecycle, supporting formulation, production, and pre-use stages. It enables formulation optimization, quality control during manufacturing, investigation into optimal transportation and storage conditions, and research on redispersibility

1. Research and development

Ensure excellent dispersibility and uniformity through raw material selection.

2. Production and quality control

Optimize production processes, including method, time, and temperature, to enhance efficiency.

3. Storage and transportation

Evaluate formulation stability under varying environmental conditions, observing destabilization, and predict shelf life.

4. Pre-use treatment

Study the reversibility of destabilization and compliance with usage standards.

Features & Benefits

Non-destructive stability analysis for various dispersions

- Non-contact, non-dilution, non-shearing

- Sample volume fraction up to 95%

- Particle size measurement range from 0.01 to 1,000 μm

Fast and direct stability measurement

- The high-performance LED and ultra-sensitive detectors, with a 20-micron scan step, allow real-time monitoring and capture of subtle variations 200 times faster than the naked eye

- Temperature control up to 80 °C to accelerate destabilization

Qualitative and quantitative stability results

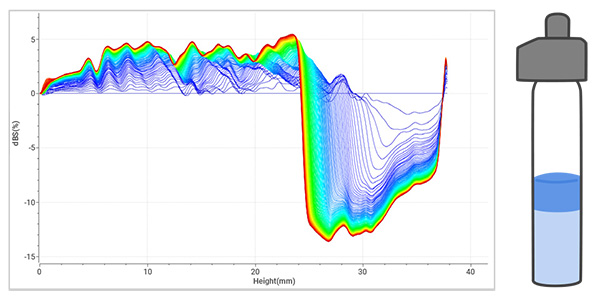

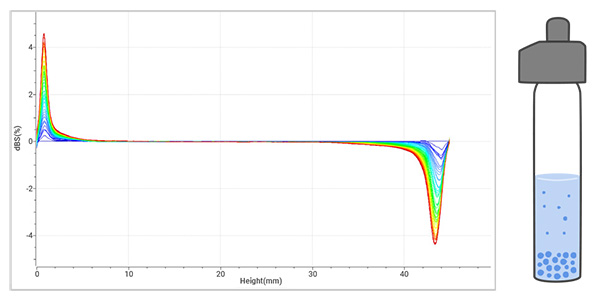

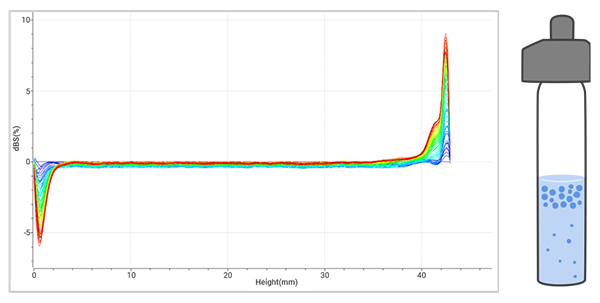

- Identification of various unstable phenomena, such as creaming, sedimentation, flocculation, coalescence, and phase separation

- Quantification of destabilizations and study of kinetics

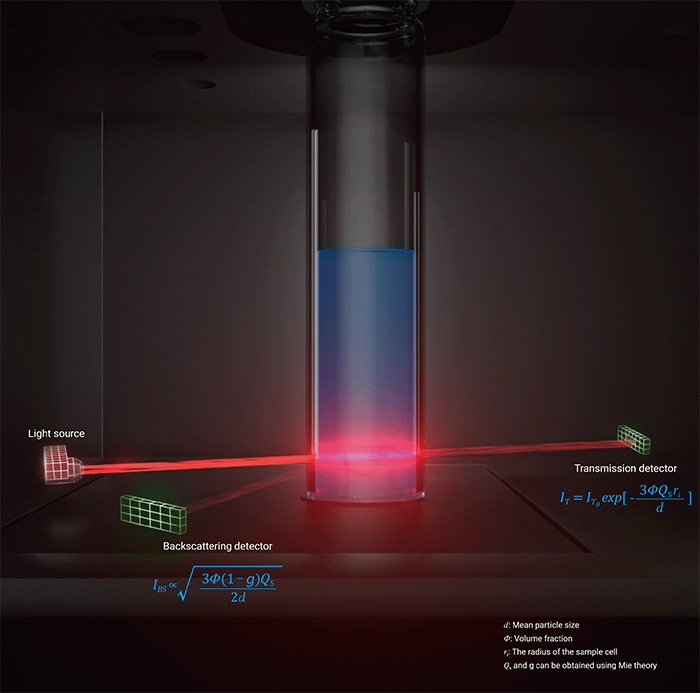

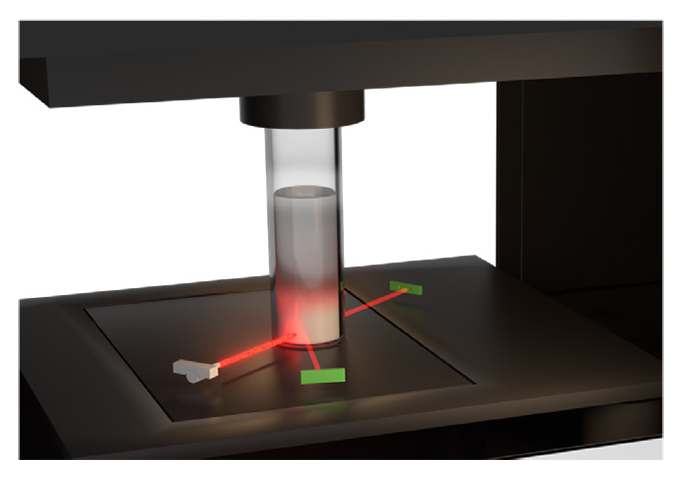

Advanced Measurement Principle

Static Multiple Light Scattering (SMLS) is employed to characterize the stability of dispersions. Within BeScan Lab, a setup comprising two detectors and an LED light source ascends along the sample cell to conduct sample scanning. In the case of concentrated samples, the backward detector is employed to detect backscattered signals, while for diluted samples, the forward detector is utilized to detect transmitted signals.

Versatile Applications

- Agrochemicals

Evaluate the stability of pesticide formulations to predict shelf life and ensure the consistent performance of suspension systems.

- Battery and Energy

Test the stability of electrode materials and electrolytes, crucial for enhancing battery performance and lifespan.

- Ceramics

Analyze the stability of ceramic slurries and monitor the stability of glazes and pigments, ensuring reliable production processes.

- Home and Personal Care

Ensure product stability in cosmetics, lotions, creams, and other formulations for reliable performance.

- Food and Beverage

Test the stability of food products, from milk to sauces, and assess the dispersibility of food powders to maintain product quality.

- Petrochemicals

Monitor and ensure the stability of oil products, providing critical insights into the long-term performance of lubricants and the behavior of polymers in oil.

- Pharmaceuticals

Conduct stability testing for medicinal formulations, assess long-term drug stability, and analyze biomacromolecule aggregation to ensure product efficacy.

- Paints, Coatings and Inks

Measure the stability of coatings and inks, and evaluate the dispersion of pigments and dyes for uniform product quality.

Curated Resources

Related Instruments

-

Bettersizer 2600

Laser Diffraction Particle Size Analyzer

Measurement range: 0.02 - 2,600μm (Wet dispersion)

Measurement range: 0.1 - 2,600μm (Dry dispersion)

Measurement range: 2 - 3,500μm (Dynamic imaging)

-

BetterPyc 380

Gas Pycnometer

Technology: Gas Displacement Method

Temperature Range: 10 - 65 ℃

Resolution: 0.0001 g/cm³

-

BeNano 180 Zeta Max

Nanoparticle Size and Zeta Potential Analyzer

Particle size measurement via sedimentation technology

Refractive index measurement

Particle concentration measurement

-

PowderPro A1

Automatic Powder Characteristics Tester

Operation Mode: Automatic

Tapping Speed: 50 - 300 taps/min

Repeatability: ≤3% variation