The Do's and Don'ts of Sieving

2024-12-27PPA 1

The Do's and Don'ts of Sieving

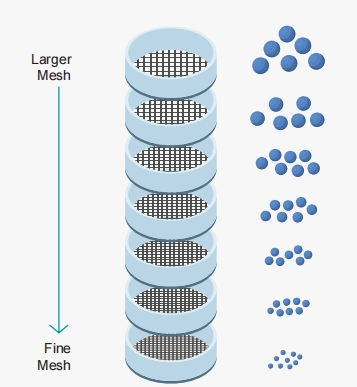

Sieving is one of the most commonly used methods for particle size analysis, especially in industries like pharmaceuticals, food, chemicals, and materials science. It involves passing a sample through a set of sieves with different mesh sizes to separate particles based on size. However, like any analytical technique, there are specific best practices that need to be followed to ensure accurate and reliable results. In this article, we’ll cover the do's and don'ts of sieving, providing essential guidance to avoid common pitfalls and optimize your sieving process.

The Do's of Sieving

- Do Calibrate Your Equipment Regularly

Calibration is crucial for obtaining accurate results. Ensure that your sieving equipment, including the sieve shaker and individual sieves, is calibrated according to the manufacturer's guidelines. Regular calibration minimizes errors in mesh opening sizes, directly affecting particle size determination.

- Do Use Clean, Dry Sieves

Before starting your sieving process, inspect and clean the sieves thoroughly to remove any residual particles from previous analyses. Even small amounts of contamination can affect your results. Additionally, ensure the sieves are completely dry, as moisture can alter the particle behavior during sieving.

- Do Select the Appropriate Mesh Size

Choose the right sieve mesh size for the sample you are testing. The selection should be based on the expected range of particle sizes in your sample. Using mesh sizes that are too large or too small for your sample will lead to inaccurate results and ineffective sieving.

- Do Maintain Consistent Sieving Time

Sieving is a process that relies on time for efficient particle separation. Be consistent with the sieving time for each batch to ensure reproducibility. Varying the sieving time can result in inconsistent results due to incomplete particle separation. - Do Use a Gentle and Consistent Motion

When operating the sieve shaker, ensure a smooth and consistent motion. A vigorous shaking motion can cause particles to become wedged in the mesh, leading to blockages and incomplete separation. Gentle agitation allows particles to pass through the sieve openings efficiently. - Do Record Results Accurately

After sieving, ensure that you record all relevant data, such as the weight of particles retained on each sieve and the total sample weight. This data is crucial for calculating particle size distribution and analyzing the efficiency of the sieving process.

The Don'ts of Sieving

- Don’t Overload the Sieve

Overloading the sieve with too much sample can cause clogging, uneven distribution, and inaccurate results. Sieves are designed to handle a certain amount of material, and exceeding this limit can impair the sieving process.

- Don't Use Damaged or Worn Sieves

Using sieves with damaged mesh or worn edges can lead to inaccurate particle size analysis. Check the sieves for any signs of wear and tear before use. If the mesh is torn or the frame is bent, replace the sieve to avoid compromising the results.

- Don’t Skip Sample Pre-Treatment

If your material requires drying, breaking up, or homogenizing before sieving, don’t skip these steps. Moist or clumpy materials can cause poor flow through the sieve, leading to inaccurate sizing. Always ensure the sample is properly pre-treated, especially for powders that tend to absorb moisture or clump together, to ensure smooth and effective sieving. - Don’t Mix Samples

Mixing different types of powders or particles can lead to misleading results. Sieving relies on the properties of the sample to segregate particles by size, and mixing incompatible samples can introduce errors.

- Don’t Neglect Proper Storage of Sieves

Improper storage of sieves can lead to damage or deformation of the mesh, affecting their accuracy and longevity. Always store sieves in a dry, clean environment, away from direct sunlight and extreme temperatures. Ensure they are stored flat or in protective cases to prevent distortion or contamination from external elements. Proper storage helps maintain the integrity of the sieves and ensures reliable results during future use.

- Don't Forget to Clean the Sieve After Every Use

It may be tempting to skip cleaning after a sieve test, but this can lead to contamination and inaccurate results in future tests. Always clean your sieves thoroughly after use to ensure they are free from any particles that could affect the outcome of subsequent analyses.