Using BeScan Lab for High-Efficiency Evaluation of Dispersant Effects on 3D Printing Slurry Stability

2024-07-24Application Note

The BeScan Lab stability analyzer, using advanced static multiple light scattering technology, is an innovative tool for the 3D printing industry. It directly assesses the dispersion stability of zirconia particles in slurries with various dispersants without requiring sample dilution, capturing subtle changes within the slurry. BeScan Lab simplifies the evaluation of slurry formulations, providing detailed analysis in just 24 hours.

| Product | BeScan Lab |

| Industry | Additive Manufacturing |

| Sample | 3D Printing Slurry |

| Measurement Type | Stability |

| Measurement Technology | Static Multiple Light Scattering (SMLS) |

Jump to a section:

Background

Zirconia (ZrO2) is vital in industries such as dentistry, medical implants, and electronics due to its excellent mechanical properties and biocompatibility. 3D printing has expanded zirconia's applications, especially in precision ceramic components, making high stability essential for high-quality printing.

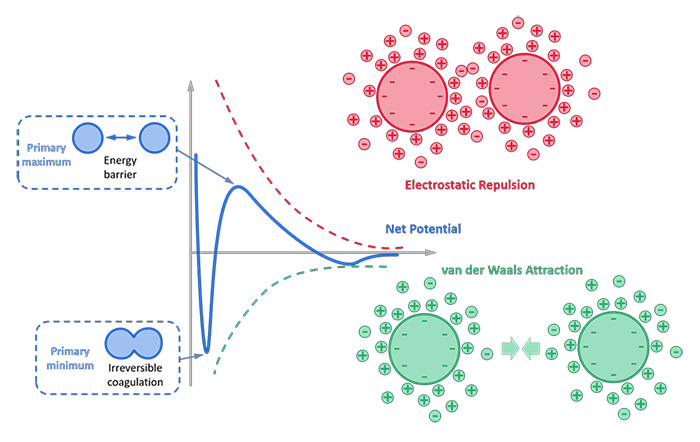

Nanoscale or microscale zirconia powders possess large surface areas, which often lead to agglomeration due to van der Waals forces. According to DLVO theory, the stability of colloids hinges on a delicate balance between electrostatic repulsion and van der Waals attraction. Stable colloids are maintained when electrostatic repulsion dominates; conversely, when attractive van der Waals forces prevail (as depicted in Figure 1), aggregation occurs. Furthermore, the agglomeration of particles increases their size, accelerating the sedimentation process.

Figure 1. DLVO theory

High-solid-content zirconia slurries require steric repulsion in addition to electrostatic forces to prevent aggregation. Dispersants provide steric hindrance by adsorbing onto particle surfaces and altering their zeta potential and hydrophobicity. The effectiveness of steric repulsion depends on the dispersant's molecular weight and concentration, forming a saturated adsorption layer for optimal stability.

Traditional stability assessment methods, such as visual inspection and particle size analysis, have limitations in handling complex compositions, are prone to environmental interference, and incur high long-term costs.

To address these issues, this study employs the BeNano 180 Zeta Pro and BeScan Lab stability analyzers. These advanced tools provide comprehensive stability evaluations under various dispersants and concentrations, supporting the 3D printing of zirconia ceramics. By precisely assessing slurry stability quickly and conveniently, researchers can enhance the quality and efficiency of the 3D printing process.

Principle

BeScan Lab utilizes Static Multiple Light Scattering (SMLS) technology, directing 850 nm light pulses vertically into the sample. Data is collected at 20 µm intervals, monitoring fluctuations in the backscattering and transmission levels over time to detect sample instability.

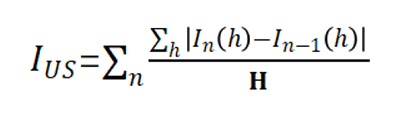

Governed by the Mie theory, signals of transmitted and backscattered light directly correlate with particle concentration (φ) and size (d). BeScan Lab provides an Instability Index (IUS) to assess the stability of dispersions, calculated by summing signal variations across sample height and time. A higher IUS indicates lower stability, automatically determined for each scan using a specific formula:

|

|

Figure 2. BeNano 180 Zeta Pro and BeScan Lab

Experimental

This study investigates the effects of four different types and concentrations of dispersants on high solid content (>50% wt) nanoscale zirconia slurries. The objective is to identify the optimal dispersant formulation that enhances slurry performance during the 3D printing process. Detailed sample information is provided in Table 1:

Table 1. Slurries Information

| Sample | #1 | #2 | #3 | #4 |

| Dispersant | 2.0% A | 4.0% A | 4.0% B | 2.0% A+ 2.0% B |

1. Zeta Potential Measurement

Adjustments in dispersant type and concentration were implemented to optimize the zeta potential, enhancing slurry dispersion and stability. Zeta potential serves as a critical indicator of particle surface charge, pivotal for formulation refinement. Considering the high sample viscosity, prior to measurement, samples were diluted to ensure a homogeneous suspension. Zeta potential measurements were conducted at 27.5°C.

2. Stability Assessment

Slurry stability was evaluated using the BeScan Lab stability analyzer. Following ultrasonic treatment, 15 mL of each of the four slurry samples was transferred into sample cells. Samples were scanned every 10 minutes at a constant temperature of 30°C over a duration of 16 hours.

Result

1. Zeta Potential Results

The zeta potential results offer crucial insights into the surface charge characteristics of zirconia slurries, directly influencing their stability. Table 2 illustrates that all samples exhibit positive zeta potentials with high absolute values, which is essential for preventing aggregation and maintaining slurry stability. The high zeta potential values suggest strong inherent mechanisms that ensure effective dispersion, crucial for achieving high-quality 3D printed products.

Table 2. Zeta Potential Results

| Sample | Zeta Potential (mV) |

| #1(2% A) | 61.27 |

| #2(4% A) | 65.55 |

| #3(4% B) | 61.52 |

| #4(2% A + 2% B) | 59.84 |

The results demonstrate that increasing the concentration of dispersant A significantly enhances the zeta potential of the slurry, evident from the increase from 2% in sample #1 to 4% in sample #2. This positive correlation highlights the role of dispersant A in improving slurry stability. In contrast, dispersant B shows less effective enhancement of zeta potential compared to dispersant A, as observed in sample #3. Sample #4, which combines both dispersants A and B, exhibits a zeta potential lower than expected, indicating potential interactions between the dispersants that may mitigate their individual effectiveness.

2. Stability Results

1) Delta Backscattered Signal

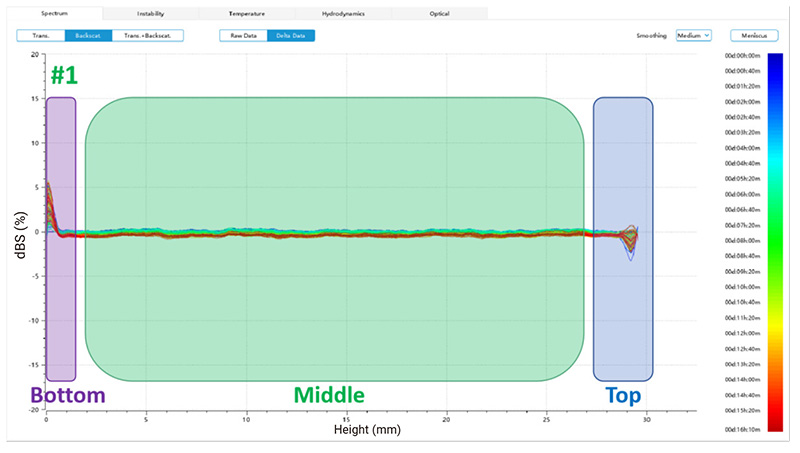

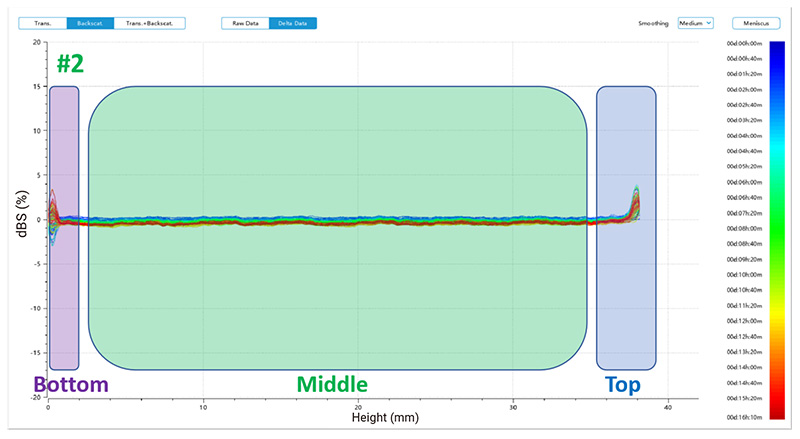

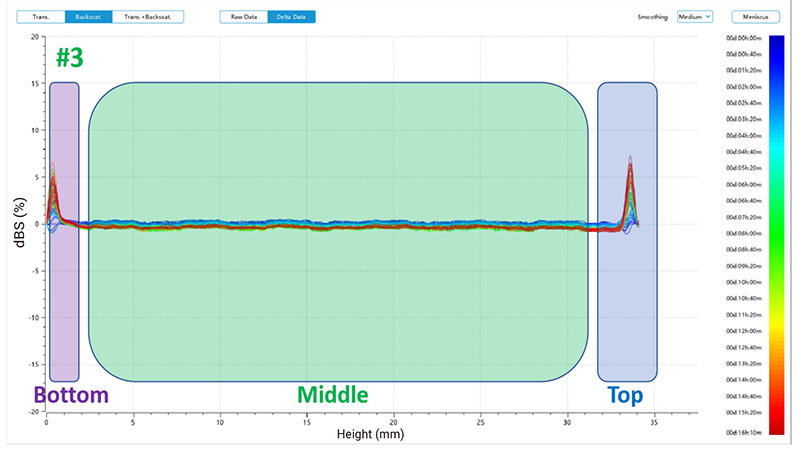

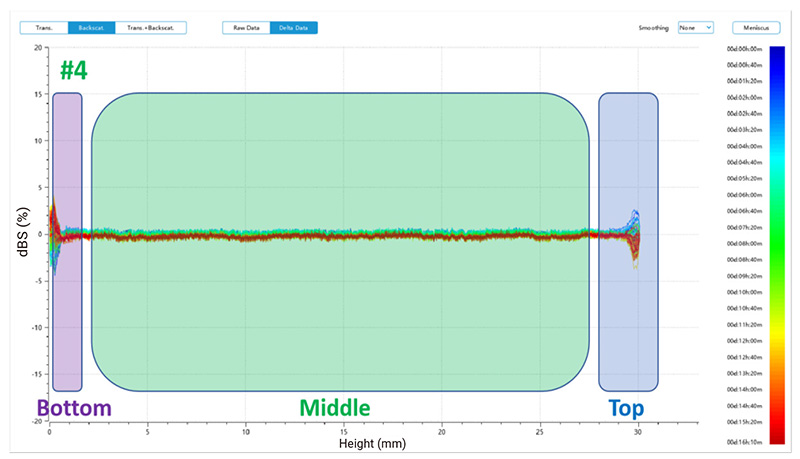

The figures illustrate the changes over time in the backscattered light delta signal (dBS) of the four slurry systems , indicating variations in sample height. During a 16-hour stability measurement, this study evaluated four different formulations of zirconia slurries. The results indicated that all formulations exhibited good stability with minimal variations and similar behavioral characteristics.

Figure 3. Delta backscattered signals (dBS) of the four slurries

At the top, the backscattered signal initially increased and then decreased, which suggests that particles in the high-solid-content slurry migrated downward, resulting in a reduced particle concentration at the top.

At the bottom, the backscattered signal initially decreased and then increased, indicating sedimentation and the formation of hard sediment.

In the middle, the weakening backscattered signal indicated slight particle aggregation, leading to the formation of clusters larger than 0.6 micrometers.

These observations collectively show a tendency for sedimentation and slight aggregation in all slurry systems. To further quantify dispersion stability, an instability index (IUS) was used for analysis, providing deeper insights into the slurry stability.

2) Global Instability

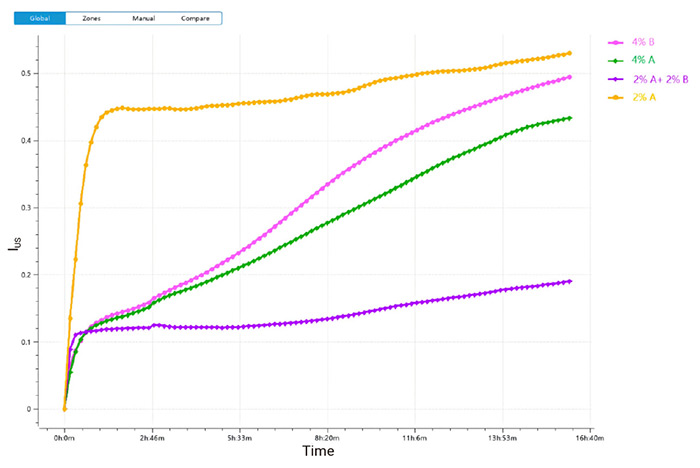

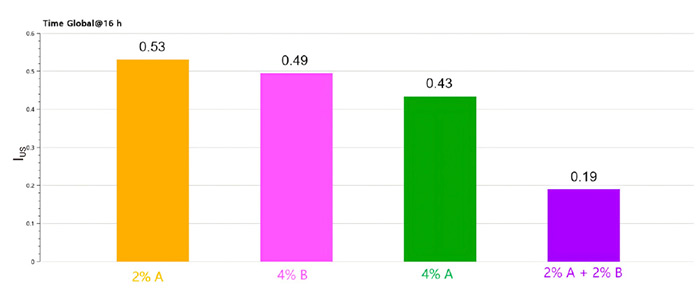

The global instability index (IUS) monitors changes in sample instability over aging time. The IUS accounts for all subtle changes in the sample, such as creaming, sedimentation, and size variation. At any given time point, a higher IUS value signifies lower sample stability.

Figure 4. Global stability dynamics comparison of the four slurries

Figure 5. Instability index of the four slurries @ 16 h

The results (shown in Figures 4 and 5) clearly illustrate the overall instability of the different 3D printing slurry formulations. All samples had IUS values below 0.5 except for sample #1, indicating good dispersion stability. Notably, formulation #2, with 4% dispersant A, exhibited significantly improved stability compared to formulation #1, which contained only 2% dispersant A. This highlights the crucial role of dispersant concentration in enhancing slurry dispersion. An optimal amount of dispersant can create a saturated adsorption layer, providing essential steric repulsion to effectively counteract van der Waals forces and prevent particle agglomeration.

Taking into account the zeta potential results, sample #4, despite having a lower zeta potential, demonstrated the best stability due to the synergistic effect of the two dispersants. These findings show that in preparing high-solid-content, low-viscosity zirconia ceramic slurries, steric repulsion is as important as, if not more critical than, electrostatic repulsion.

Therefore, the appropriate selection and dosage of dispersants to enhance both electrostatic and steric repulsion are essential for achieving slurry stability.

Conclusion

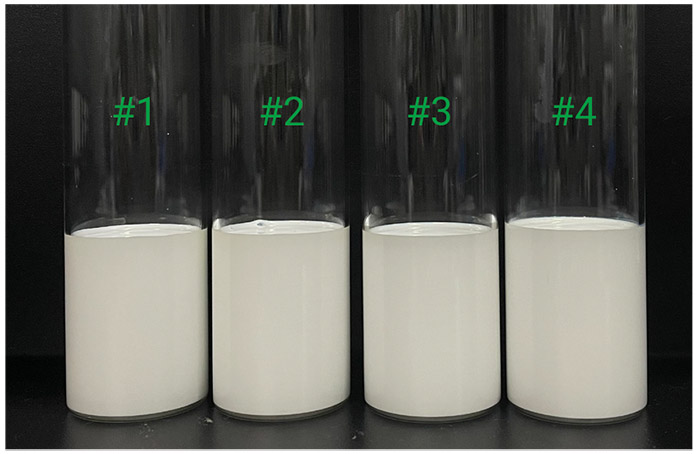

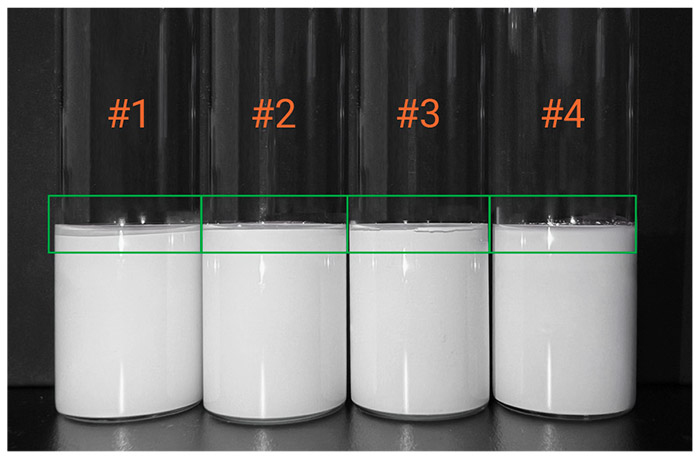

The BeScan Lab stability analyzer, using advanced static multiple light scattering technology, is an innovative tool for the 3D printing industry. It directly assesses the dispersion stability of zirconia particles in slurries with various dispersants without requiring sample dilution, capturing subtle changes within the slurry. BeScan Lab simplifies the evaluation of slurry formulations, providing detailed analysis in just 24 hours. Its high sensitivity ensures accurate detection of sample instability. Our system, validated through continuous observation over 10 months, delivers results that match traditional methods, as shown in Figure 6, proving its effectiveness in slurry stability assessment.

Figure 6. Before measuring (up) and after 10 months(down)

About the Authors

|

Xin Yan Application Engineer @ Bettersize Instruments |

|

Dr. Hui Ning Chief Product Officer @ Bettersize Instruments |

|

BeScan Lab Stability Analyzer

|

|

Recommended articles

Rate this article