Particle Size and Tapped Density Analysis of Anode Materials of Lithium-ion Batteries

2024-09-16Application Note

The particle size and tapped density of anode materials play a pivotal role in the performance of Lithium-ion batteries. This study employs the Bettersizer 2600 laser diffraction particle size analyzer and BeDensi T3 Pro tapped density tester to investigate the effects of varying blending ratios of two samples on their D50 and tapped density. The results may provide valuable guidance for developing advanced electrode material formulations, thereby fostering advancements in battery technology.

| Product | Bettersizer 2600, BeDensi T3 Pro |

| Industry | Battery and Energy |

| Sample | Graphite |

| Measurement Type | Particle Size, Tapped Density |

| Measurement Technology | Laser Diffraction, Powder Characterization |

Jump to a section:

Introduction

As the demand for portable electronic devices and electric vehicles continues to rise, the battery market is experiencing rapid growth, which requires batteries with faster charging, higher energy density, and better cycling performance[1].

The properties of raw graphite as an anode material are crucial for battery performance. The particle size of graphite has a significant impact on the kinetics of lithium-ion intercalation and deintercalation, as well as on the formation and stability of the Solid Electrolyte Interphase (SEI) film[2]. Tapped density, a measure of the bulk behavior of powder raw materials, also affects energy density; Higher tapped density enables a battery to store more energy in the same volume.

This application note explored the particle size and tapped density of four raw graphite using a laser diffraction analyzer and tapped density tester. Additionally, how the different blending ratios with two samples affect these properties of the mixture was discussed.

Measurement

The Bettersizer 2600 laser diffraction particle size analyzer with the BT-802 wet dispersion unit was used to measure the D50 values (the particle size corresponding to the cumulative frequency of 50%), based on Mie theory. In this study, approximately 50 mg of graphite was sampled, and alkylbenzene sulfonate was added as the surfactant to the graphite sample. The measurements were conducted at a rotational speed of 1200 rpm and an ultrasonic duration of 30 seconds.

Bettersizer 2600

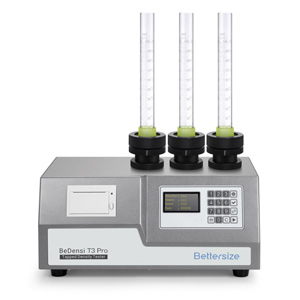

The BeDensi T3 Pro tapped density tester was used to measure the tapped density. In detail, a 250 mL graduated cylinder with a 50 g sample of graphite was tapped for a specific tapped number at 250 taps/min. The measured density was obtained by the given formula below:

Where x represents the cumulative number of taps, ρ denotes the density, m stands for the mass, and V represents the volume.

BeDensi T3 Pro

Results

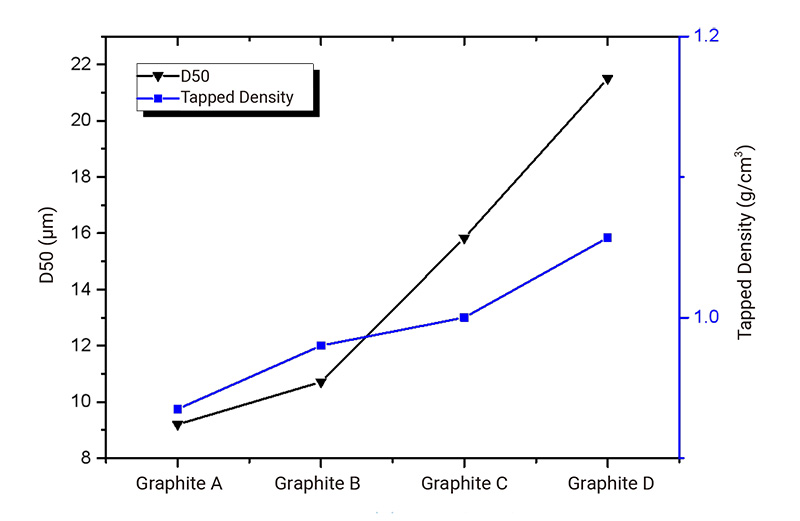

The D50 and its tapped density are presented in Table 1 and Figure 1. The tapped density increases with the increase of the D50. Larger particles achieve higher tapped densities by more effectively filling the voids between particles, reducing the interparticle space compared to smaller particles. A higher tapped density is beneficial for enhancing the battery's energy density; however, this increase is accompanied by a rise in particle size, which may lead to negative consequences.

Table 1: The D50 and tapped density of graphite samples

| Sample | D50 (μm) | Tapped density (g/cm3 ) |

| Graphite A | 9.2 | 0.9349 |

| Graphite B | 10.71 | 0.9801 |

| Graphite C | 15.83 | 1.0000 |

| Graphite D | 21.50 | 1.0568 |

Figure 1 The D50 and tapped density of graphite samples

As a result, a mixture of coarse and fine particles is commonly used in the anode to balance tapped density with particle size.

Table 2 shows the D50 and tapped density for samples A and D at various blending ratios. Within a certain range, as the proportion of fine particles (A) in the mixture increases, the D50 decreases, and the tapped density increases. Because small particles can fill the gaps between large particles, the higher the proportion of small particles, the greater the tapped density. However, when there is an excess of small particles, the voids between the larger particles become saturated, and remains are small gaps between small particles. Since the tapped density of small particles is lower than that of large particles (see Table 1), consequently, beyond a certain threshold, as the proportion of fine particles in the mixture rises, the tapped density decreases.

Table 2 The D50 and tapped density of different blending ratios of graphite A and D

| Sample | Blending ratio | D50 (μm) | Tapped density (g/cm3 ) |

| D10A0 | 10:0 | 21.50 | 1.0568 |

| D8A2 | 8:2 | 18.61 | 1.0917 |

| D6A4 | 6:4 | 15.69 | 1.0788 |

| D5A5 | 5:5 | 14.62 | 1.0621 |

Conclusion

The particle size and tapped density of anode materials play a pivotal role in the performance of Lithium-ion batteries. This study employs the Bettersizer 2600 laser diffraction particle size analyzer and BeDensi T3 Pro tapped density tester to investigate the effects of varying blending ratios of two samples on their D50 and tapped density. The results may provide valuable guidance for developing advanced electrode material formulations, thereby fostering advancements in battery technology.

References

[1]. Bläubaum, L., Röder, F., Nowak, C., Chan, H.S., Kwade, A. and Krewer, U., 2020. Impact of particle size distribution on performance of lithium - ion batteries. ChemElectroChem, 7(23), pp.4755-4766.

[2].An, S.J., Li, J., Daniel, C., Mohanty, D., Nagpure, S. and Wood III, D.L., 2016. The state of understanding of the lithium-ion-battery graphite solid electrolyte interphase (SEI) and its relationship to formation cycling. Carbon, 105, pp.52-76.

About the Authors

|

Zhichao Han Application Engineer @ Bettersize Instruments |

|

Perfil Liu Senior Application Engineer @ Bettersize Instruments |

|

Weichen Gan Application Engineer @ Bettersize Instruments |

|

Bettersizer 2600 Laser Diffraction Particle Size Analyzer |

|

|

|

|

Rate this article