Optimize the Dispersion of Battery Materials for a Better Laser Diffraction Particle Size Test

2024-03-08Application Note

Accurate measurement of lithium iron phosphate (LFP) particle size distribution (PSD) is crucial for optimizing battery performance. This study explores the challenges associated with LFP PSD measurement and proposes a tailored solution through pre-dispersion with ultrasonication.

The optimal pre-dispersion settings, identified through a series of tests, involve ultrasonication at 510W for 1 minute. This approach yields a stable PSD with a D100 value of 10.27 μm and exhibits excellent repeatability, complying with ISO 13320 standards. This approach empowers researchers and engineers to optimize LFP battery performance and accelerate the development of sustainable energy solutions.

| Product | Bettersizer 2600 |

| Industry | Battery and Energy |

| Sample | Lithium iron phosphate (cathode, battery) |

| Measurement Type | Particle size |

| Measurement Technology | Laser Diffraction |

Jump to a section:

- Introduction

- Measurement Design

- Maintaining Measurement Integrity: Addressing Abnormal PSD and Obscuration Trends

- Overcoming Unsaturated Dispersion with Tailored Pre-Treatment

- Conclusion

Introduction

The burgeoning electric vehicle (EV) revolution hinges on the development of high-performance, sustainable energy solutions. However, range limitations continue to pose a significant challenge. While lithium-ion batteries offer a promising avenue, lithium iron phosphate (LFP) batteries, lauded for their exceptional safety and economic viability, face a trade-off: lower gravimetric energy density compared to their counterparts, such as lithium nickel manganese cobalt oxide (NMC) or lithium nickel cobalt aluminum oxides (NCA). This translates to diminished driving ranges and prolonged charging times, impeding the widespread adoption of LFP batteries on EVs.

Fortunately, a key lies in meticulously tailoring the particle size of LFP battery materials. The size of LFP particles within the battery profoundly impacts the performance of batteries. Examining the operational mechanism of LFP batteries reveals that particle size plays a crucial role in the following aspects:

1. Smaller LFP cathode particles have a larger surface area compared to their volume. A larger surface area allows for more lithium ions to participate in the reaction with the cathode particles. Thus, more lithium ions can be stored and released, making the battery able to hold more energy without adding the battery size.

2. Smaller LFP particles form a finer porous structure among them, allowing the electrolyte to penetrate more easily into the cathode structure, facilitating better ionic transport, and enabling the battery to charge and discharge quickly.

In a nutshell, with a finer LFP cathode material size, researchers and development engineers can unlock enhanced energy density, accelerated charging rates, and extended range, all while preserving the inherent safety and cost-effectiveness that make LFP batteries so attractive to the EV industry.

However, things are not as simple as "the thinner particle size, the better battery performance". Since smaller LFP particles are more prone to mechanical degradation during cycling (charging and discharging), they reduce the battery's lifespan. Also, while smaller particles offer a porous structure to permit electrolytes to penetrate more easily, relatively more void space between LFP particles also reduces the overall energy density of the battery. Therefore, finding the optimal particle size is crucial for balancing the benefits of high surface area with the need for good lifespan, and to utilize the energy density. This optimization depends on the specific cathode material status and the intended application of the battery.

To solve the performance dilemma of single-sized LFP particles, the optimal solution may lie in a mixed particle size distribution (PSD). By strategically combining particles of varying sizes, a balance between the advantages offered by each individual size fraction can be easily achieved. Smaller particles ensure sufficient surface area for lithium-ion interaction, while larger ones help maximize packing density and structural stability. Thus, for superior battery performance, precisely measuring and analyzing the complex PSDs of LFP materials is becoming vitally important for LFP lithium battery providers, no matter it is single-sized LFP components or complex distributed mixtures.

Measurement Design

Optimal PSD control presents significant challenges. Compared with traditional methods like sieving, Laser Diffraction Particle Size Analyzers offer a powerful and precise solution to accurately characterize the intricate particle size distribution within LFP electrode materials. This advanced technique utilizes the principles of light diffraction to measure particle size across a wide size range, providing researchers with highly accurate and reproducible data.

To meet the demand for high-performance LFP lithium batteries, Bettersize Instruments offers the Bettersizer 2600 for precise PSD measurements in the industry. This instrument optimizes the laser diffraction method, accurately measuring particle size in the range of 0.02 - 2600 μm. Its unique optical design allows versatility for various sample states, from dry powder to wet slurry, with efficient switching between dispersion and feeding units.

In this study, synthesized micron-size LFP particles are taken as samples in a state of dry powders. The LFP samples were dispersed in water due to their insolubility. Considering maximizing the data reliability, a BT-802 large-volume automatic dispersion unit is used with the Bettersizer 2600 main unit to make the PSD measurement. Since LFP particles are of a large density compared with water, to avoid sedimentation, the stirring speed is set to 1800 rpm.

Bettersizer 2600 with BT-802

Maintaining Measurement Integrity: Addressing Abnormal PSD and Obscuration Trends

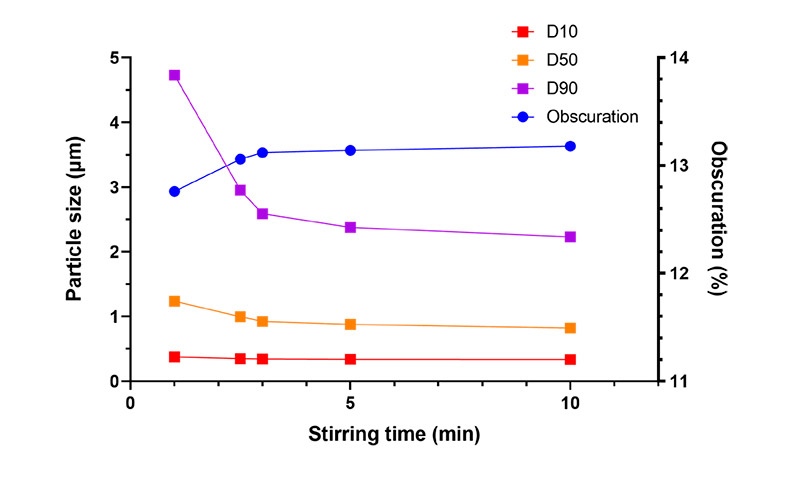

To ensure the reliability of PSD results, a series of tests are done with the same LFP sample, and the same sampling method, but with different stirring/circulation times. With the extended time of stirring and circulating the sample suspension, the PSD result showed a tendency to decrease while the obscuration value was increasing, as shown in the following figure 1.

Figure 1. Abnormal PSD and Obscuration Trends

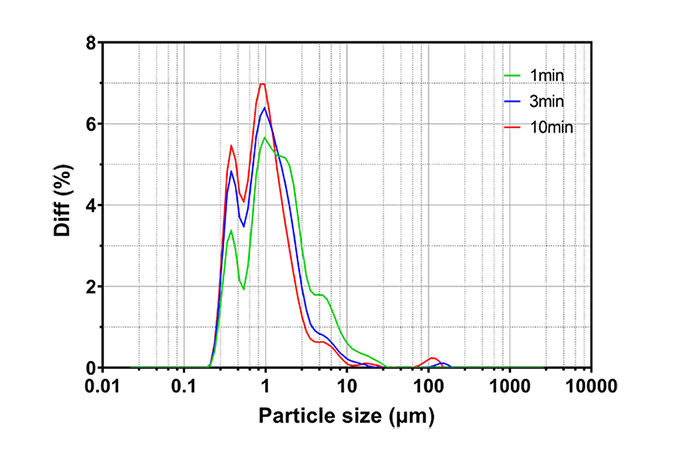

In most cases, a typical trend is more likely to be observed: prolonged stirring led to a stable PSD and a consistent obscuration value. However, the LFP samples exhibited a counterintuitive behavior: the PSD decreased with longer stirring, while the obscuration increased. Furthermore, the observed trend in LFP samples suggests a more complex scenario: the PSD "differentiation" indicates a dual process (Figure 2)

- Dispersion: A main population of particles is fragmenting into smaller ones, even after 10 minutes of stirring. This suggests that the stirring forces are insufficient to fully break apart the aggregates, leading to a gradual reduction in average particle size.

- Agglomeration: A smaller number of particles are agglomerating into larger ones, contributing to the increased obscuration.

Figure 2. The PSD "differentiation" phenomenon

This seemingly paradoxical phenomenon points towards an unstable state within the sample suspension, also known as unsaturated dispersion, which highlights the limitations of traditional stirring dispersion methods for LFP samples. The shearing forces generated by the stirring mechanism are insufficient to overcome the inherent cohesive forces holding the LFP particles together, leading to incomplete dispersion and the observed "differentiation" process.

Overcoming Unsaturated Dispersion with Tailored Pre-Treatment

To solve this problem caused by unsaturated dispersion, more dispersion energy is needed to help the agglomerated particles be dispersed in a short time. The 2-stage dispersion, including a pre-dispersion stage and the dispersion stage while measurement, can be applied here. In this case, a thicker suspension was prepared by mixing LFP dry powders with deionized water, and the pre-disperse stage was done with the thicker suspension.

Harnessing Ultrasonic Energy for Effective Dispersion

To overcome the limitations of traditional stirring methods, ultrasonication is proven to be an effective pre-dispersion step. This technique utilizes high-frequency sound waves to generate intense shear forces, effectively breaking apart agglomerated LFP particles and promoting a more uniform suspension. The prepared thicker suspension was ultrasonicated and then diluted with the BT-802 before actual PSD measurements. Every test was done immediately after adding samples in BT-802 to form a stable suspension.

Finding the Optimal Pre-Dispersion Strategy:

This investigation involved a series of tests exploring different ultrasonication power and duration combinations. The results (Table 1) paint a clear picture: sufficient dispersion energy is crucial for achieving a stable PSD. This energy can be delivered through either increased ultrasonication power or extended treatment time.

Table 1. PSD typical value of different ultrasonication power and duration combinations

|

Power (W) |

Typical Value (μm) |

30 seconds |

1 minute |

3 minutes |

5 minutes |

|

270W |

D10 |

0.328 |

0.327 |

0.324 |

0.325 |

|

D50 |

0.817 |

0.773 |

0.758 |

0.762 |

|

|

D90 |

4.740 |

2.426 |

2.323 |

2.242 |

|

|

360W |

D10 |

0.330 |

0.327 |

0.326 |

0.324 |

|

D50 |

0.813 |

0.757 |

0.746 |

0.752 |

|

|

D90 |

3.039 |

2.970 |

2.354 |

2.344 |

|

|

420W |

D10 |

0.324 |

0.324 |

0.324 |

0.324 |

|

D50 |

0.731 |

0.728 |

0.729 |

0.724 |

|

|

D90 |

1.830 |

1.790 |

1.755 |

1.753 |

|

|

510W |

D10 |

0.325 |

0.326 |

0.324 |

0.324 |

|

D50 |

0.724 |

0.722 |

0.721 |

0.719 |

|

|

D90 |

1.726 |

1.706 |

1.703 |

1.705 |

|

|

570W |

D10 |

0.325 |

0.325 |

0.325 |

0.325 |

|

D50 |

0.719 |

0.715 |

0.718 |

0.719 |

|

|

D90 |

1.693 |

1.707 |

1.708 |

1.704 |

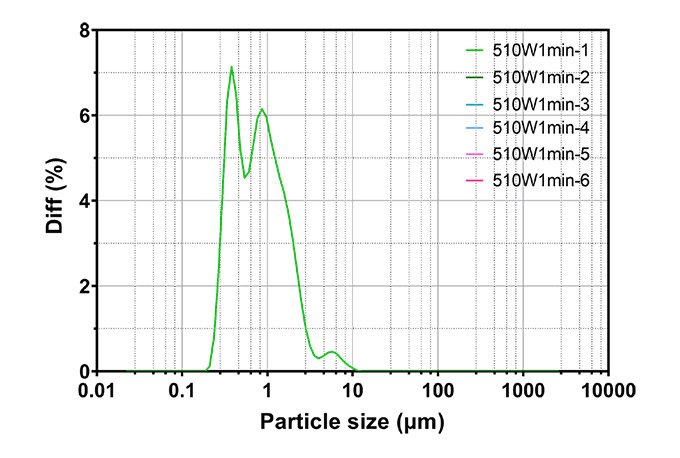

Striking a Balance: 510W and 1 Minute for Optimal Results

Seeking a balance between power and efficiency, 510W for 1 minute can be easily identified as the optimal pre-dispersion setting for the LFP sample under investigation. This configuration effectively dispersed the particles, leading to a stable PSD with a D100 value of 10.27 μm.

Validation through Repeatability Testing:

To ensure the reliability of this pre-dispersion approach, six repeated measurements were conducted. The results, presented in Figure 3, demonstrate excellent repeatability. The standard deviations for D10, D50, and D90 values were remarkably low (0.12%, 0.05%, and 0.09%, respectively), demonstrating full compliance with ISO 13320 requirements.

Figure 3. Repeatability test of PSD measurement procedure

Conclusion

Precise control of LFP particle size distribution plays a pivotal role in battery performance. Laser diffraction analysis, exemplified by the Bettersizer 2600, offers a valuable tool for monitoring PSD in the lithium battery industry. However, for LFP materials with unique dispersion challenges, the implementation of an optimized pre-dispersion procedure, such as the ultrasonication method described here, proves essential. This study demonstrates the effectiveness of this approach, showcasing its ability to achieve stable, reliable, and repeatable PSD measurements, ultimately empowering researchers and engineers to optimize LFP battery performance.

About the Author

|

Weichen Gan Application Engineer @ Bettersize Instruments |

|

Unlock the secrets to high-performance Lithium-ion batteries with the collection of SEVEN battery application notes. (pdf) |

|

Recommended articles

Rate this article