The Importance of Particle Size and Roundness Analysis for 3D Printing

2020-08-17Application Briefs

3D Printing, is a kind of rapid prototyping technology, also known as additive manufacturing. This technology is based on digital model files, which uses adhesive materials such as powder metal or plastic to construct objects by printing layer by layer in 3 dimensions. 3D printing has been made possible by using a digital technology material printer. It is often used in mold manufacturing, industrial design and other fields to make models/parts eventually used in the direct manufacturing of products. Printing of parts by using this technology is a common occurrence today and is rapidly replacing other technologies which have traditionally been used. The technology has applications in jewelry, footwear, industrial design, construction, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering and firearms to name but a few.

Factors that affect 3D Printing

The particle size distribution, roundness, chemical composition, oxygen content and fluidity of the powder all affect the performance indices of 3D printed parts.

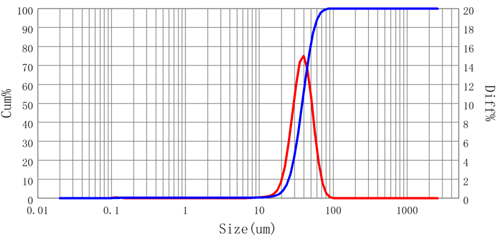

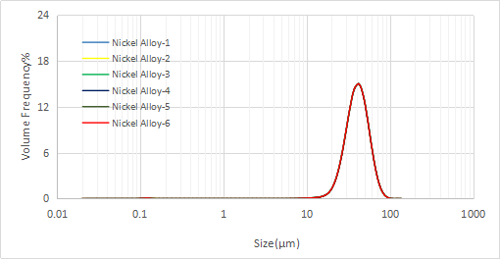

At present, the particle size ranges of powder commonly used in metal 3D printing is 15-53μm, 53-105μm, and can be extended to 105~150μm in some cases. This particle size range to be used is dependent on the different energy sources of metal printers. Printers which use a laser as an the energy source, because of its fine focusing spot and the relative ease with which it can melt fine powders, and the size range of 15~53 μm powder is suitable for use. A Plasma beam can be used as an energy source for the printer when melting coarse powder and uses 53-105μm powder.

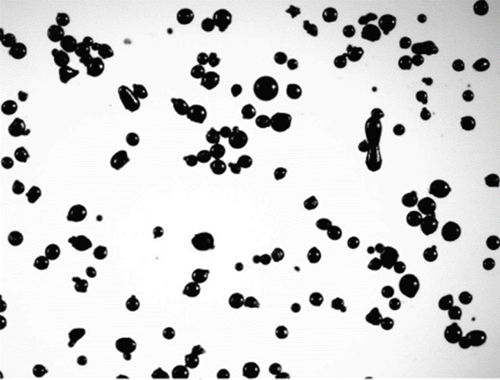

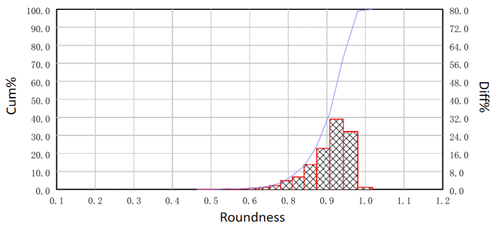

Roundness is the measure of proximity of the metal powder particles to a circle and its range is from 0-1, with perfect spheres having a value of 1. Fluidity is the ability of a substance to flow easily and its value is determined from the time it takes for a certain mass of metal powder to flow through a measuring tool with a specified aperture (s/50g). Generally speaking, the higher the roundness value the better the flowability, of the powder particles. This in turn means it is easier to control the powder laying and feeding during metal 3D printing, and thus obtain parts with higher printing quality.

Particle size analysis of Nickel Alloy Powder

High quality 3D-printed metal products are achieved when the large and small particles of the metal powder are mixed in appropriate proportions. According to the above introduction, it is very important to detect the particle size and distribution of metal powder. At present, laser particle size analyzer is generally used to detect the particle size and distribution of such metal powders. The following is the test of nickel alloy powder.

Figure 1. Particle size distribution diagram of single nickel alloy sample

Figure 2. Particle size analysis of nickel alloy sample in Bettersizer 2600 measurement

Roundness analysis in Nickel Alloy Powder

Spherical or sub-spherical powder has good fluidity, thus it is much less likely to plug the powder supply system during the printing process. Also spherical powder is easier to spread into a thin layer, and thus the dimension accuracy and surface quality of 3D printed parts is improved. In addition the density and uniformity of the parts is improved also making spherical powders the preferred raw material for 3D printing. The following is the roundness analysis in Nickel Alloy Powder.

Figure 3. Image of nickel alloy sample in BeVision S1 measurement

Figure 4. Roundness analysis of nickel alloy sample in BeVision S1 measurement

Conclusion

There are signs that 3D printing is receiving tremendous focus globally from industrial manufacturing. As the 3D printing technology matures and develops, more and more applications are being discovered weekly to meet the personalized needs of every consumer to the maximum extent. For some particularly complex parts that are difficult to process and do not require mass production, 3D printing has a strong competitive advantage. To maintain this competitive advantage control the particle distribution and roundness is a must in order to provide the better quality product in the additive manufacturing.