Comprehensive Flowability Assessment of Collagen Powders Using Carr Index Method

2024-11-22Application Note

This study evaluates the flowability of three commercially available collagen powders using the PowderPro A1. By employing the Carr Index method[1], a comprehensive analysis of the powders’properties—including angle of repose, compressibility, density, and uniformity—was conducted, which can offer valuable insights for powder analysis in the pharmaceutical industry.

| Product | PowderPro A1 |

| Industry | Pharmaceuticals |

| Sample | Collagen Powders |

| Measurement Type | Powder Characteristics |

| Measurement Technology | Carr Index Method |

Jump to a section:

- Introduction

- Instrument and Sample Description

- Experimental Data Analysis and Comparison

- Overall Analysis and Bridge-Breaking Necessity

- Conclusion

- Reference

Introduction

Flowability is a crucial property in the handling and processing of collagen powders across industries such as pharmaceuticals, food, and cosmetics. Ensuring optimal flowability is essential for achieving high-quality products, as it impacts various aspects of manufacturing, including mixing, compaction, and packaging. Poor flowability can lead to production inefficiencies, inconsistent dosing, and ultimately, compromised product performance.

The Carr Index method is a robust method for evaluating powder flowability, based on a combination of measurements. Each parameter contributes valuable insights into collagen powder's behavior:

- Angle of repose is the steepest angle at which a pile of powder material remains stable when poured onto a surface, reflecting the internal friction between particles.

- Angle of Spatula is the angle formed between a spatula and the surface of a powder pile when gathering or handling powder, offering insights into powder behavior during handling.

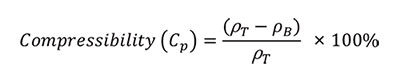

- Compressibility, which is calculated from the bulk density (ρB) and tapped density(ρT), reveals the extent to which a powder can be compacted, indicating potential issues with flow under compression.

The calculation of the compressibility:

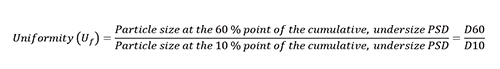

- Uniformity measures the potential of powder clumping and the consistency of particle size distribution.

Instrument and Sample Description

The PowderPro A1 is a versatile, high-performance instrument capable of measuring and analyzing 14 different powder characteristics, including critical parameters like angle of repose, compressibility, and tapped density. Beyond offering individual parameter measurements, the instrument also provides a comprehensive flowability analysis based on the Carr Index method. This method integrates multiple parameters to give a more complete assessment of powder behavior, streamlining comparisons and making it ideal for research and development across various industries.

PowderPro A1

In this study, three collagen powders, labeled Collagen 1, Collagen 2, and Collagen 3, were evaluated based on the Carr Index method. These powders, representing different price segments, were analyzed to investigate the relationship between flowability and other physical properties.

Experimental Data Analysis and Comparison

- Angle of Repose and Angle of Spatula: Collagen 1 and Collagen 3 show better flowability and handling, with lower angles of repose and spatula. In contrast, Collagen 2’s higher values indicate poor flowability and handling challenges.

- Density and Compressibility: Collagen 2 has the highest value of compressibility and densities among the three samples, indicating increased inter-particle friction and poor flowability, which may lead to compaction and dosing challenges compared to the other two samples.

- Uniformity and Consistency: Uniformity is one of the critical factors for PSD consistency; thus, Collagen 3's lowest uniformity value among these samples may suggest it has a more uniform distribution and improves performance in various applications.

Table 1. Flowability evaluation of three collagen powder samples by PowderPro A1

| Measuring Items | Collagen 1 | Collagen 2 | Collagen 3 | |||

| Value | Index | Value | Index | Value | Index | |

| Angle of Repose (°) | 37.97 | 18 | 47.71 | 12 | 33.56 | 21 |

| Angle of Spatula (°) | 53.43 | 16 | 63.16 | 12 | 42.38 | 18 |

| Tapped Density (g/cm3 ) | 0.45 | 0.59 | 0.56 | |||

| Bulk Density (g/cm3 ) | 0.35 | 0.41 | 0.49 | |||

| Compressibility (%) | 22.22 | 16 | 31 | 10 | 12.50 | 21 |

| Uniformity | 2.88 | 23 | 3.61 | 23 | 2.70 | 23 |

| Evaluation of Flowability | ||||||

| Flowability Index | 73 | 57 | 83 | |||

| Evaluation | Good | Not Good | Fairly Good | |||

| Necessity of bridge-breaking measures | Sometimes vibrator is required | Required | Not required | |||

Overall Analysis and Bridge-Breaking Necessity

The flowability index rates Collagen 1 as "Good," Collagen 3 as "Fairly Good," and Collagen 2 as "Not Good," indicating that Collagen 2 requires mechanical aids like vibration to address bridging issues. Its poor flowability, high compressibility, and steep angle of repose highlight the need to consider density and friction in powder handling.

In summary, Collagen 3 shows superior flowability and handling properties among these three samples. The overall evaluation underscores the advantage of assessing collagen powder's flowability through multiple test parameters, emphasizing that compressibility, uniformity, angle of repose and angle of spatula are key factors indicating flow behavior and product quality. Customer feedback further supports this conclusion, with Collagen 3 receiving higher ratings for its better dissolution and enhanced consumption experience.

Conclusion

The Carr Index method, utilized in the PowderPro A1, is an essential tool for comprehensive powder characterization. By evaluating multiple parameters, it offers a holistic view of powder flowability, which is vital for predicting and optimizing powder performance in practical applications. These insights are vital for industries reliant on powder processing to maintain product quality and consistency.

Reference

1. Carr, R.L. (1965) Evaluating Flow Properties of Solids. Chemical Engineering Journal, 72, 163-168.

About the Author

|

Feiqing Shen Application Engineer @ Bettersize Instruments |

|

|

PowderPro A1 14-in-1 Powder Characteristics Tester

|

Rate this article