Measure Coffee Particle Size And Shape With Bettersize To Achieve The Perfect Flavor

2025-04-09Industry Solution

For exceptional coffee, grind size is critical. The Bettersizer 2600 combines laser diffraction and dynamic imaging to deliver precise particle size and shape analysis—essential technology for coffee producers and equipment manufacturers seeking consistent quality and competitive advantage.

Navigate to a Section:

Coffee is not just a beverage—it’s a carefully calibrated science of flavor, aroma, and texture. With billions of cups consumed every day, producers and enthusiasts alike know that the secret to a superior brew lies not only in the bean’s origin or roast level, but in the coffee particle size achieved during grinding. Whether crafting a cold brew coffee grind size for extended steeping or dialing in the perfect coffee grind size for drip, the consistency and distribution of the particles profoundly affect extraction quality. Every preparation method—from French press and pour-over to espresso—demands a specific grind fineness. Coarse grind coffee retains the boldness needed for immersion brews, while fine grind coffee delivers the intensity required for espresso’s quick pressure-extraction. Even within medium grind coffee, subtle variations in coffee grain size can lead to under- or over-extraction, altering the drink’s flavor profile dramatically.

Despite the importance of precision, achieving consistent coffee ground size is no simple task. Coffee powder is a complex, organic material—prone to agglomeration, irregular in shape, and difficult to handle in bulk. Grain coffee particles vary not only in size but also in morphology, which affects flow behavior and filterability. Inconsistent coffee grind size can result in uneven extraction, making one cup overly bitter and the next bland. The challenges of sieving coffee by traditional means have highlighted the need for more accurate, reproducible methods to measure and control coffee grind consistency. Accurate analysis of coffee grain parameters—both in size and shape—is critical to developing a reliable grinding profile. With advanced solutions like Bettersizer 2600, a laser diffraction particle size analyzer, coffee producers can go beyond guesswork and establish precise, data-driven control over every batch of ground coffee.

How Does Grind Size Affect Coffee

Grind size is one of the most decisive variables in determining how coffee extracts during brewing, and ultimately, how it tastes in the cup. At its core, grinding coffee transforms roasted beans into particles with vastly increased surface area—unlocking flavors, oils, and soluble compounds that define the sensory experience. But not all grind sizes behave the same way in the presence of water. Coarse grind coffee, often used for French press or cold brew, allows for a lower extraction rate. Optimal extraction with coarse ground results in a smooth, mellow, sometimes sweet taste. In contrast, fine grind coffee, as required by espresso machines, allows water to pass through slower even under pressure, creating an intense, full-bodied shot. In contrast, fine grind coffee, as required by espresso machines, allows water to pass through quickly under pressure, creating an intense, full-bodied shot in seconds.

The coffee grind size must be carefully tailored to the brewing method’s specific time and temperature conditions. For example, the ideal cold brew coffee grind size is coarse, enabling a long steep time without over-extraction. Conversely, the coffee grind size for drip methods like automatic brewers or pour-overs typically falls into the medium range, balancing flow rate and contact time for a clean, flavorful brew. If the grind is too coarse for the method, under-extraction occurs—leaving the coffee sour, watery, or weak. If it’s too fine, over-extraction sets in, leading to bitterness, astringency, and an overly strong or harsh profile.

Furthermore, the coffee grind consistency—not just the average size—plays a crucial role. A mixture of particle sizes (known as "fines" and "boulders") can cause uneven extraction: some particles release flavor too quickly, while others hardly contribute at all. This inconsistency affects not only taste but also the repeatability of brewing, especially in commercial settings where quality control is paramount. Understanding and controlling coffee ground size is not just a matter of taste preference, but of process optimization—ensuring that every grain of coffee contributes precisely what it should to the final brew.

Challenges in Measuring Coffee Grind Size and Consistency

Measuring coffee grind size and consistency may seem straightforward at a glance, but in practice, it presents a series of complex challenges rooted in the physical properties of ground coffee itself. Once roasted beans are broken down into particles, they no longer resemble neat, uniform shapes; instead, they exhibit broad size distributions, irregular forms, jagged edges, and a tendency to agglomerate. These factors complicate efforts to characterize the grind using traditional methods such as simple sieving, which often fails to capture the full variability of the particle population.

One of the primary difficulties lies in the diverse range of coffee powder types used across different brewing methods. Coarse grind coffee for French press or cold brew contains large, irregular particles with a wide size spread, while fine grind coffee for espresso is composed of powder-like grains with high surface area and increased electrostatic charge. These variations affect how particles behave during measurement—clumping, sticking to equipment surfaces, or passing through sieves inconsistently. Moreover, different roast levels can influence grind behavior: darker roasts are more brittle and tend to produce more fines, while lighter roasts grind more evenly but may fracture unpredictably.

Even with a consistent grinder setting, achieving uniform coffee grind size is notoriously difficult. Most grinding processes yield a mixture of large fragments and ultrafine dust. This makes it challenging to define a single coffee ground size that accurately represents the batch. Standard deviation in particle size is often as important as the median size itself, particularly when precision is required—such as in industrial settings where brew quality must remain consistent across large volumes.

Additionally, sieving coffee only provides partial insight, as it is limited to separating particles based on size thresholds rather than offering a complete picture of the full distribution or particle shape. Grind fineness is not just a matter of how small the particles are—it also involves their morphology, density, and behavior in water. That’s why modern coffee analysis increasingly turns to advanced techniques capable of evaluating both particle size and shape in real time. This is where solutions like those from Bettersize become indispensable, offering detailed insights that go far beyond what manual methods can achieve.

How Do You Measure Coffee Grounds

While grind size plays a critical role in shaping coffee's extraction behavior, its impact cannot be fully understood without precise, repeatable measurement. Knowing how fine or coarse your coffee isn’t just about touch or visual judgment—it requires scientific accuracy, particularly when consistency and quality control are the goals. This is where particle size measurement comes into focus, offering a quantitative lens through which the grinding process can be evaluated and optimized.

For decades, traditional methods like manual sieving and microscopy have served as the primary tools for estimating coffee ground size. However, these approaches are often limited in scope, labor-intensive, and subject to human error. They can’t provide a complete view of particle size distribution or shape—two critical metrics that significantly influence how coffee behaves during brewing. Modern laboratories and coffee researchers now rely on advanced particle size analyzer to gain a deeper, more accurate understanding of their grind characteristics.

Among the leading solutions in this field is the Bettersizer 2600, an advanced laser diffraction system designed to deliver high-resolution particle size and particle shape analysis. This system stands out for its patented combination of Fourier and inverse Fourier optical designs, supported by an array of 92 detectors that capture scattered light across an ultra-wide angular range—from as low as 0.016° to as high as 165°. This configuration allows it to measure both ultra-fine and coarse coffee particles, making it ideal for assessing diverse grind profiles used in methods ranging from Turkish coffee to cold brew. For more information or to schedule a demonstration, please contact the Bettersize Team at info@bettersize.com

high-resolution particle size and particle shape analysis by Bettersizer 2600

One of the key innovations in the Bettersizer 2600 is its tilted sample cell, which minimizes total internal reflection and enhances signal clarity. This means more light reaches the detectors, leading to greater measurement accuracy, particularly when analyzing samples with complex or irregular morphology—such as roasted coffee. Additionally, the instrument supports refractive index measurement, helping resolve the optical complexity inherent in dark, porous materials like ground beans.

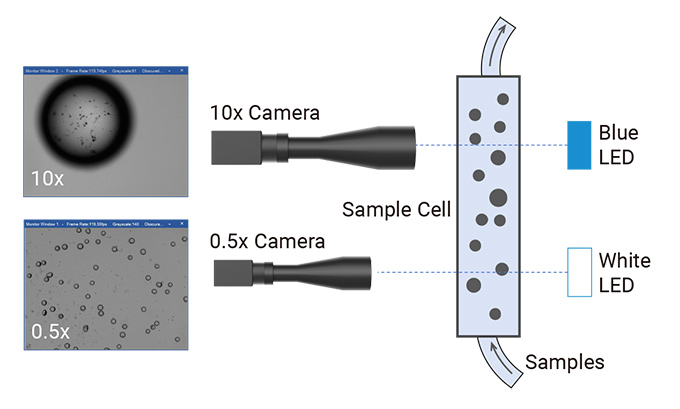

But particle size is only part of the story. The Bettersizer 2600 also incorporates the PIC-1 dynamic imaging module, a dual-camera system capable of capturing real-time images of particles as they pass through the flow cell. This adds an entirely new dimension to particle size analysis, enabling users to assess not just size distribution, but also shape characteristics—such as elongation, roundness, and aspect ratio. For coffee, where grind uniformity and the presence of fines or oversized grains can dramatically affect extraction, this level of detail is invaluable. If you are curious to see how this technology could elevate your coffee analysis, contact Bettersize experts to answer your questions and provide personalized guidance.

Bettersizer 2600 dynamic imaging analyzer

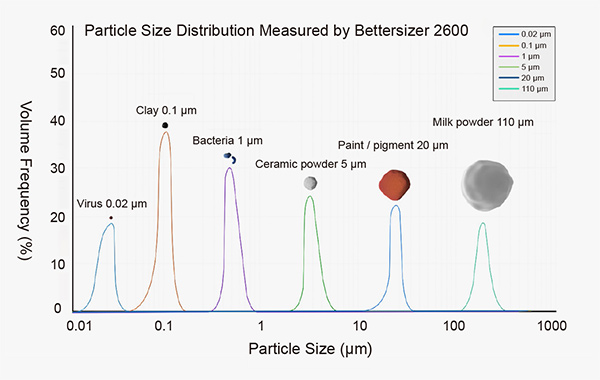

The result is a truly comprehensive understanding of coffee grind characteristics. From detecting outliers like clumps or dust particles, to monitoring grind consistency across production batches, the Bettersizer 2600 delivers actionable data that elevates both research and industrial applications. With a measurement range that spans from 0.02 µm up to 3,500 µm when combined with imaging, it covers the full spectrum of grind sizes encountered in real-world coffee processing.

As the demand for quality and repeatability in coffee continues to grow—whether in artisan cafés, specialty roasters, or industrial production—precise particle size measurement becomes not just a helpful tool, but an essential one. The Bettersizer 2600 redefines what’s possible in coffee grind size analysis, bridging the gap between sensory quality and scientific control.

Maximize Coffee Flavor with Bettersizer 2600 Particle Analyzer

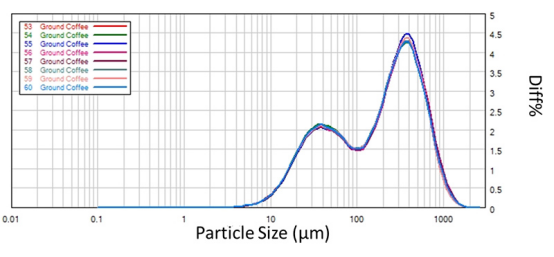

Rigorous testing demonstrates the exceptional stability and repeatability of the Bettersizer 2600

In today’s competitive coffee industry, where every nuance of taste and aroma counts, precision in particle size and shape measurement is no longer optional—it’s essential. Whether you're crafting small-batch single-origin roasts or producing high-volume commercial blends, ensuring consistency across every grind batch translates directly into cup quality and customer satisfaction. From cold brew coffee grind size to espresso’s ultra-fine particles, from grain coffee to drip filter brews, every preparation method demands a different, carefully controlled particle size profile.

Bettersize understands the science behind the grind. With the Bettersizer 2600, coffee manufacturers and processors gain access to a comprehensive particle size analyzer that doesn’t just measure size, but unlocks deeper insights through dual-laser diffraction and dynamic imaging. By simultaneously analyzing particle size distribution and shape, it enables a level of quality control that meets the rigorous standards of specialty roasters and industrial-scale producers alike.

For those who value repeatability, efficiency, and excellence in every cup, Bettersize delivers the tools to move from guesswork to granularity. Reach out to an expert to address the specific demands of your particle size measurement applications.

Rate this article