Laser Diffraction: A Powerful Particle Size Analysis Tool for Chocolate

2020-07-02Application Briefs

Chocolate, first created by a pre-Olmec race in 1900 BC, subsequently used by the Mayans and Aztecs was passed to the chocolate houses by the Spanish across Europe after 3,500 years. The manufacturing process and final characteristics of chocolate are significantly affected by particle size in many ways. Lower production costs and better chocolate quality are desirable and achievable only with the help of high-performance laser diffraction instruments. Manufacturers are able to control particle size distribution of intermediates as well as final products in chocolate production in a highly efficient way.

Particle sizing of chocolate of different types

The cocoa liquor is blended back with the cocoa butter and other ingredients in varying quantities to make different types of chocolate including white, milk and dark chocolates of varying cocoa percentages. As shown in Table 1, dark chocolate contains either few or no milk solids whereas milk chocolate does contain powdered milk. White chocolate however contains no cocoa products at all, only cocoa butter and no chocolate solids, so in reality it is not technically a chocolate at all in the real sense.

Table 1.Principal ingredients in different types of chocolates (white, dark and milk chocolate)

.png)

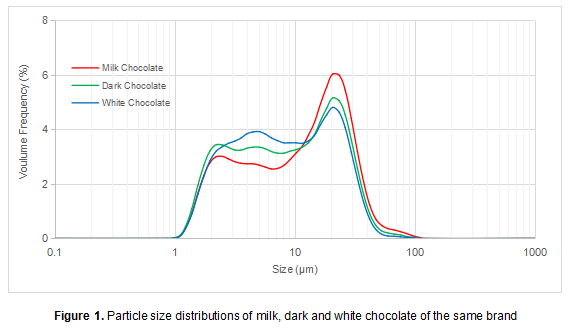

The comparison of particle size distributions (PSD) of milk, dark and white chocolates of the same brand are achieved by the Bettersizer 2600 and shown in Figure 1. It can be seen that the mean size order is milk > dark > white chocolate. The change of the coarse end of the distribution indicates the change in the cocoa particles and milk solids content required. At the coarse end of the distribution, milk chocolate has a larger percentage than the other two kinds of chocolates. On the other hand, white chocolate has a greater percentage of fine particles at around 5 μm. Despite that, the bimodal nature of PSD could be observed on either chocolate due to the presence of multiple components in the chocolate.

Particle sizing of milk chocolate of different countries

Apart from particle size variations in the different types of chocolate, are there size differences in the chocolates of the same type but produced in different countries? The answer is yes. There is no standard recipe for chocolate production globally and there will always be regional differences in its production and the particle size will of course be different. We can imagine that in order to target local customers, the chocolate sold in different places should have various particular characteristics, appropriate for the local taste such as the particular melting temperature or the mouthfeel.

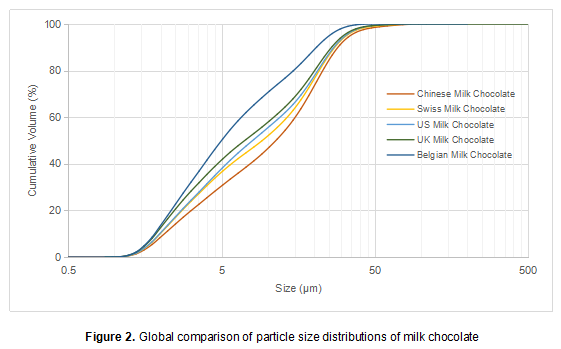

In the experiments below, five milk chocolate produced in different countries (China, Switzerland, America, UK, Belgium) were analyzed by the Bettersizer 2600 in order to investigate the regional customer preference on the mouthfeel and flavor of chocolate, which will in turn affect the manufacturing process as well as final particle size of chocolate.

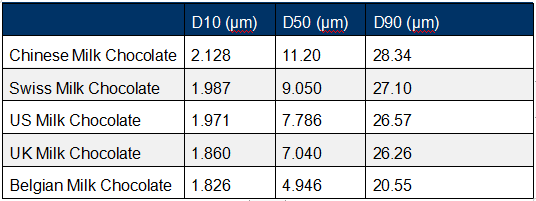

A global comparison of PSD of milk chocolate was shown in Figure 2. Significant diversities were easily observed, and the mean size sequence of milk chocolate obtained is China > Switzerland > America > UK > Belgium. Critical particle size values (D10, D50 and D90) are shown in Table 2 where a similar trend can be observed. We can thereby speculate that milk chocolate coming from Belgium or UK has undergone a longer grinding and conching time, and probably required more cocoa butter or lecithin in the manufacturing process in order to maintain the flow properties because they contain finer particles than other milk chocolate.

Table 2.Critical values of particle size distribution of milk chocolate in different countries

In conclusion, the Bettersizer 2600 successfully performed the measurements of characterizing chocolate of different types (dark, milk, white) and various countries, and has therefore been proven to be an effective tool to analyze the particle size distribution of chocolate and help chocolate manufactures produce more attractive and consistent final products.