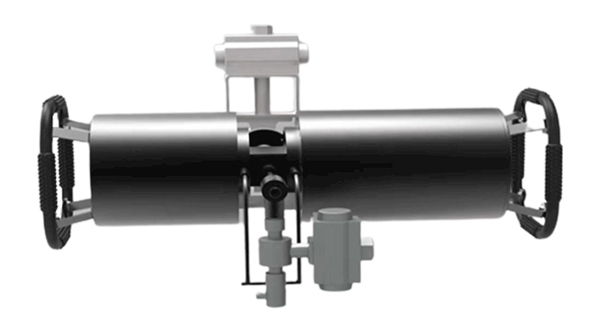

BT-Online1

Driven by Standard Operating Procedure (SOP) and integrated with different control platforms and protocols, the BT-Online1 provides real-time particle size measurement results for dry process lines 24/7. Optional feedback control can be therefore carried out. With the automatic alignment system, uninterruptible power supply (UPS), and abnormal pressure protection, the BT-Online1 possesses strong environmental adaptability, offering monitoring of the process line with minimal manual intervention.

Features and Benefits

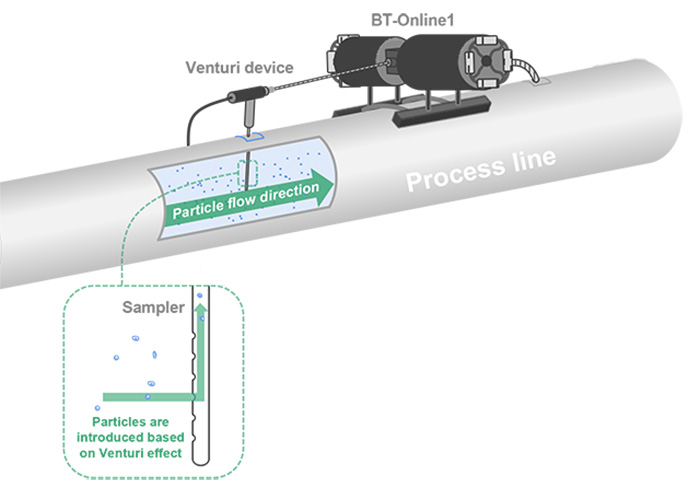

- ● Representative sampling

- ● Dual protection from contamination

- ● Monitoring of up to 4 process lines

- ● Automatic alignment

- ● Intuitive software

- ● Multiple communication protocols

Overview

BT-Online1—Online Measurement for Dry Powder

The BT-Online1 is used as an online particle size analyzer for dry particles within the size range of 0.1 to 1000 μm. The BT-Online1 is integrated into a process loop, providing real-time measurement results that assist in quality inspection and parameter monitoring.

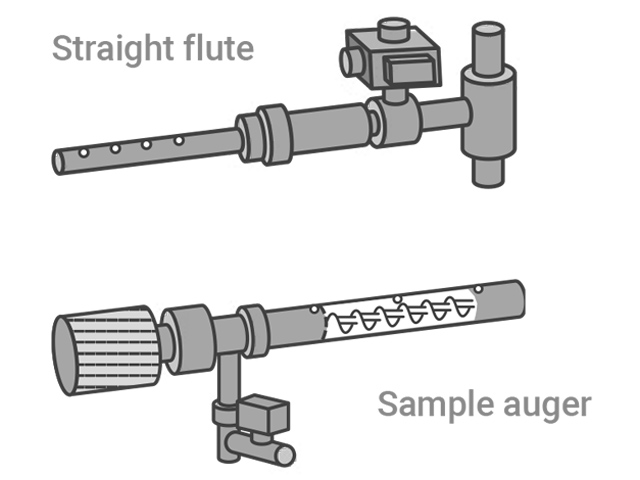

Representative sampling with two samplers

1. Straight flute

- Suitable for the sample with wide particle size distribution

- Good representative

- Simple maintenance

2. Sample auger

- Suitable for thin material flow

- Threaded rod ensures effective extraction

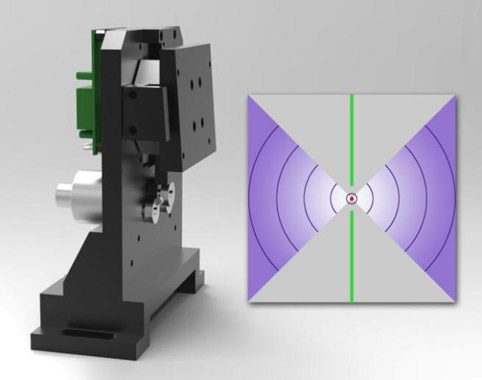

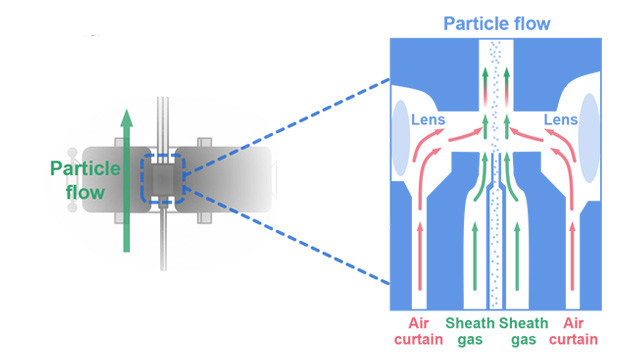

Dual protection from contamination

The lenses of the BT-Online1 are protected using a dual air curtain and sheath gas, which greatly reduce maintenance costs, increase efficiency, and prevent costly downtime.

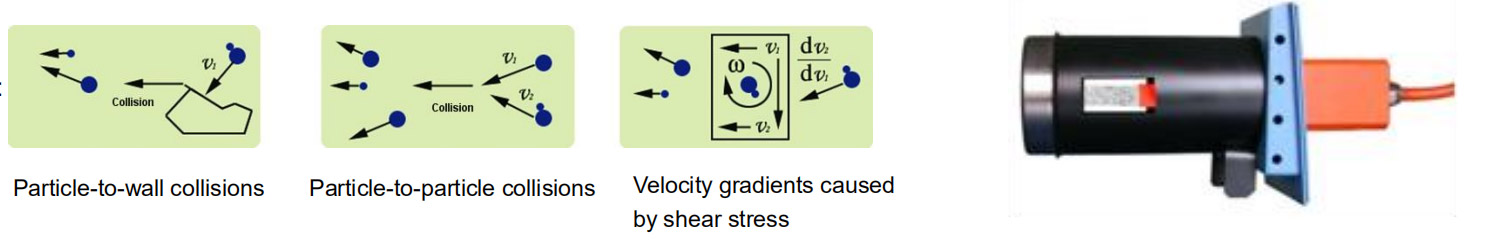

1. Dual air curtain

- Protection of lenses from contamination based on the two generated positive pressure zones

- Assistance in sample dispersion

2. Sheath gas

- Hydrodynamic focusing of the sample jet ensures the correct flowing path for the particles

- Protection of lenses from pollution using an annular curtain

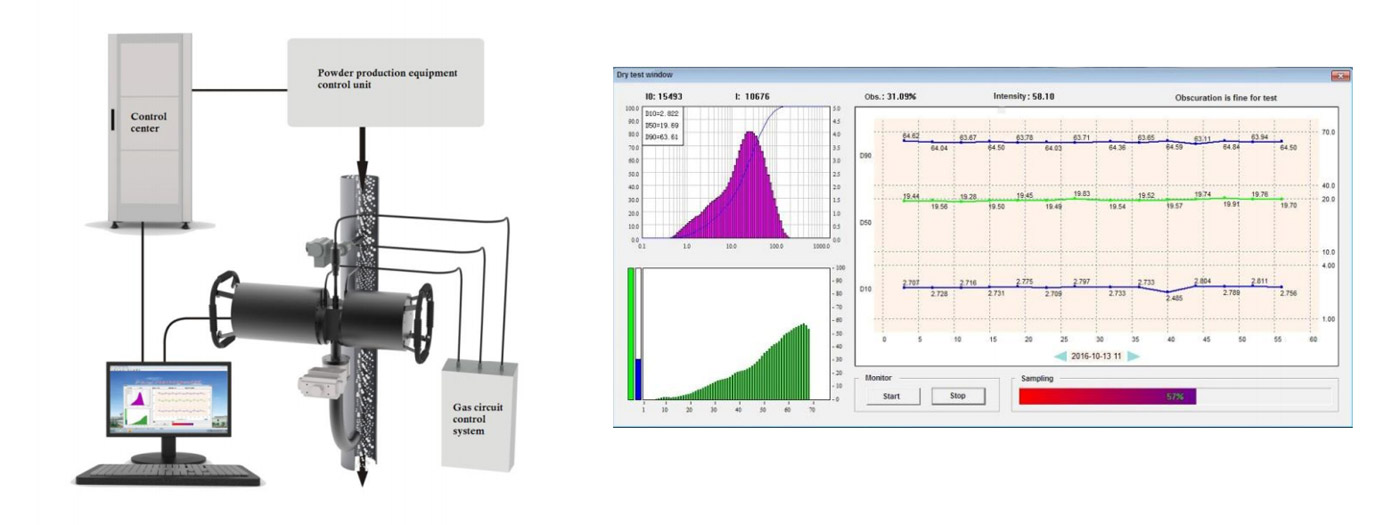

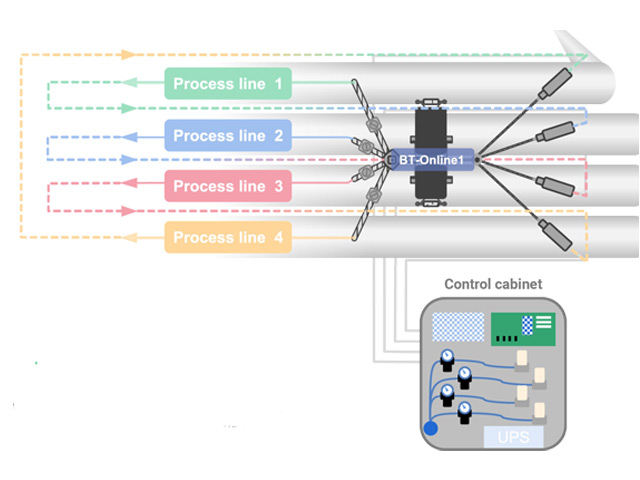

Monitoring of up to 4 process lines

The BT-Online1 can monitor up to 4 process lines, in which corresponding samplers are connected to the BT-Online1, and the samples are measured individually. This design is characterized by investment saving, space efficiency, and simplified data management.

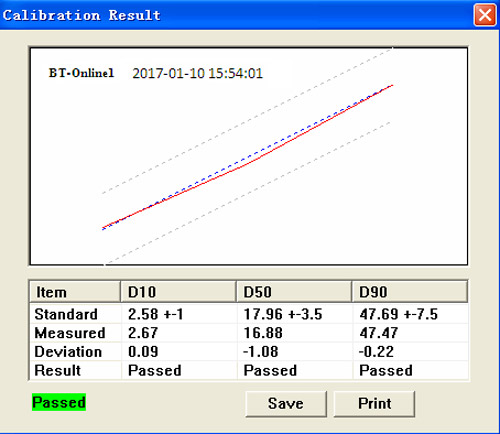

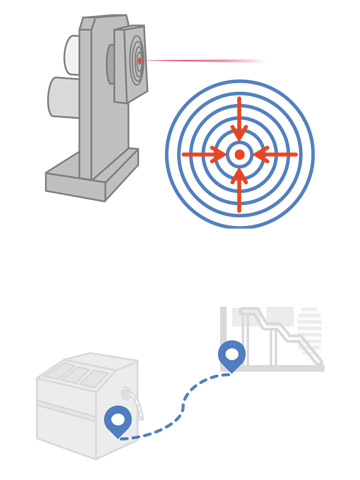

Automatic alignment

Automatic alignment will be carried out, ensuring accuracy for every measurement in case of harsh working environment.

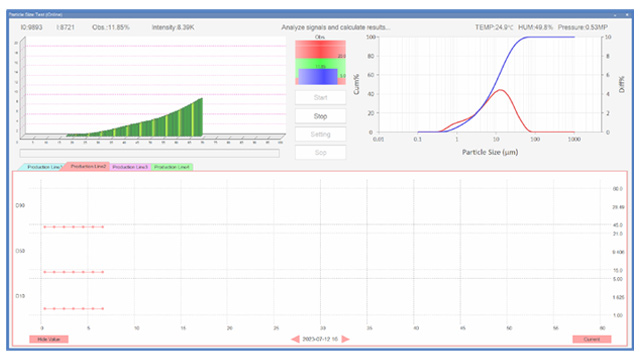

Intuitive software

Individual SOP for each process line can be configured, and monitoring curves are intuitively displayed in the software.

Multiple communication protocols

The BT-Online1 can cooperate with the DCS or PLC system of the plant. Available communication protocols are TCP, Modbus RTU, and 4 - 20 mA.

Application

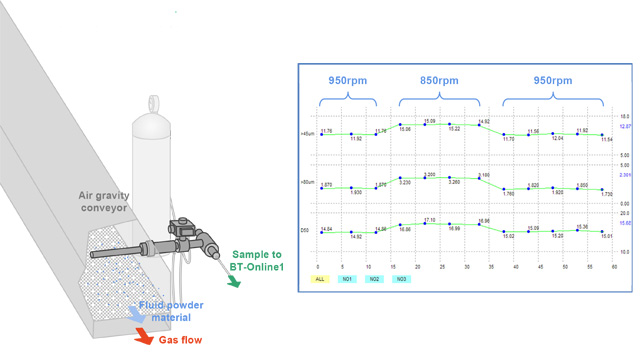

- Measurement of cement powder in air gravity conveyor

By changing the rotation speed of the classifier, the particle sizes of the cement particles measured with the BT-Online1 vary

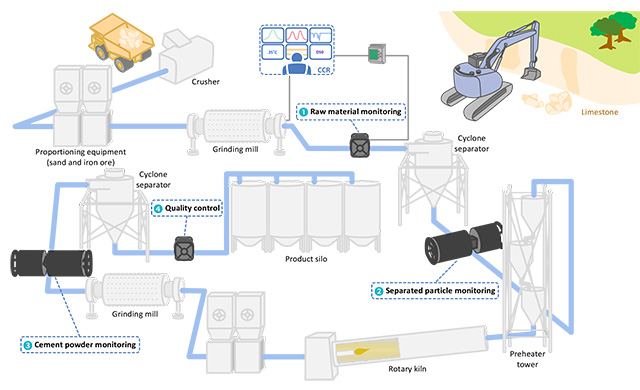

- Various application of the BT-Online1 in a cement plant

A general portland cement production line is demonstrated below. The BT-Online1 can be applied in different positions for different purposes. Examples are shown below:

- Further applications of the BT-Online1

Curated Resources

- Application Note

bigClick

bigClick2020-09-14

Measuring the Particle Size Distribution of Cement in Real Time with On-line Laser System

Related Powder Characteristics Analyzer

-

Bettersizer S3 Plus

Particle Size and Shape Analyzer

Measurement range: 0.01 - 3,500μm (Laser System)

Measurement range: 2 - 3,500μm (Image System)

-

Bettersizer ST

One-stop Particle Size Analyzer

Dispersion type: Wet

Measurement range: 0.1 - 1,000µm

Repeatability: ≤1% variation

-

Bettersizer 2600

Laser Diffraction Particle Size Analyzer

Measurement range: 0.02 - 2,600μm (Wet dispersion)

Measurement range: 0.1 - 2,600μm (Dry dispersion)

Measurement range: 2 - 3,500μm (Dynamic imaging)