Improving the Tapped Density of the Cathode Material to make a Lithium-ion Battery Hold More Energy

2021-11-08Application Note

Tapped density is one of two important physical properties of electrode materials and affects the energy density of a Li-ion battery (LIB). The other important physical property is the particle size distribution which provides the appropriate information to optimize the grinding parameters during production. Improving the tapped density can also optimize the high energy density during LIB manufacture.

Thus, it is necessary for the LIB producer to determine in advance, what is the most optimal and achievable tapped density and then use this parameter as the “gold standard” to measure samples from the process during production until they match or come close to the “gold standard” measurement. The easy-to-use BeDensi T Pro series is an ideal tapped density tester because it is an economical device which delivers exceptional performance with no compromises.

| Product | BeDensi T Pro Series, Bettersizer ST |

| Industry | Battery and Energy |

| Sample | LiFePO4 |

| Measurement Type | Powder Characteristics, Particle Size Distribution |

| Measurement Technology | Powder Characterization, Laser Diffraction |

Jump to a section:

1. Introduction

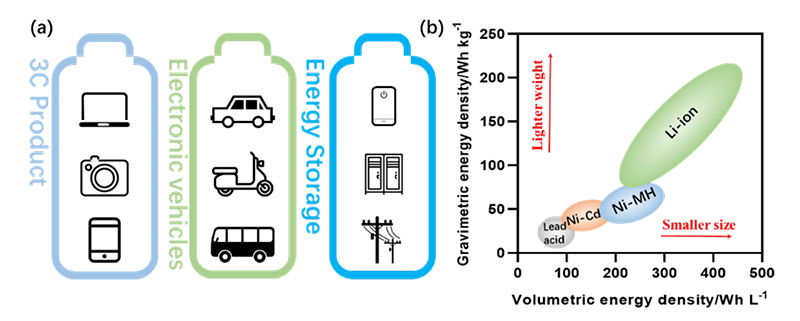

Li-ion battery (LIB) is widely used in 3C products (Computer, Communication, and Consumer Electronics), also known as “Information Appliances”. Because the size of 3C products is not large, they are often referred to as “3C small appliances”. As shown in the picture in Figure 1a other devices using LIB include electronic vehicles and stationary energy storage systems. LIB is used out of all other choices because it has the highest energy-density of practical rechargeable batteries, as demonstrated in the graph depicted in Figure 1b.

Figure 1. Applications of Li-ion battery (a) and energy density of rechargeable batteries (b).

Due to these volume-constrained applications, the volumetric energy density of a battery is a necessary parameter to consider. The volumetric energy density is the amount of energy stored per unit volume and is typically expressed in Watt-hours per liter (Wh/L). A Li-ion battery with a higher volumetric energy density will hold more energy than a similar volume one with a lower energy density. Also, when installing the LIB into the appropriate product there is often a size limitation so a smaller size higher-energy-density LIB is a definite advantage in volume-constrained systems. So far, although extensive studies have been done to increase the energy density and power in LIBs, the achieved energy storage capability is still not adequate to meet the growing markets demand. [1]

To achieve a high volumetric energy density, the active materials in the LIB cathode electrode must have high tapped density. Table 1 shows the difference between the theoretical and the tapped densities of active materials in a typical cathode. These active materials include LiCoO2 (LCO), Li (NixCoyMnz)O2 (NCM), LiFePO4 (LFP), and LiMn2O4. In general, the tapped density is massively related to the particle size, particle size distribution, morphology, etc. [2] It is expected that the density can be improved by optimizing the production process. Several parameters can specifically be optimized such as precursor preparation, calcination, and grinding. Cathode active materials are mixed with a binder or conductive agent and coated on an Aluminum collector followed by roll pressing. The packaging density of electrodes will be improved to hold more energy with the same volume.

Table 1. Theoretical and tapped density of cathode materials.

|

Cathode Materials |

Li (NixCoyMnz)O2 |

LiFePO4 |

LiMn2O4 |

LiCoO2 |

|

Theoretical density (g/cm3) |

4.85 |

3.60 |

4.31 |

5.10 |

|

Tapped density (g/cm3) |

2.6-2.8 |

0.80-1.10 |

2.20-2.40 |

2.80-3.00 |

The grinding time directly influences the particle size distribution (PSD) of the cathode powder materials. The PSD has a great influence on the tapped density. The primary goal of this application note was to see the relationship of the PSD on the tapped density of LIB cathode materials.

2. Experimental

The tapped densities of two LiFePO4 (LFP) samples prepared under different grind times were characterized using the BeDensi T2 with two workstations. The experiments were tested in accordance with ASTM B527-20 standard, with 50g sample being used to pour into the cylinder. [3] The drop height used was 3 mm and the tapping speed was 200 taps/ min and the total tapping time lasted 8 minutes. The particle size distribution of the samples was measured in less than a minute by laser diffraction using the Bettersizer ST.

3. Results

3.1 Tapped Density

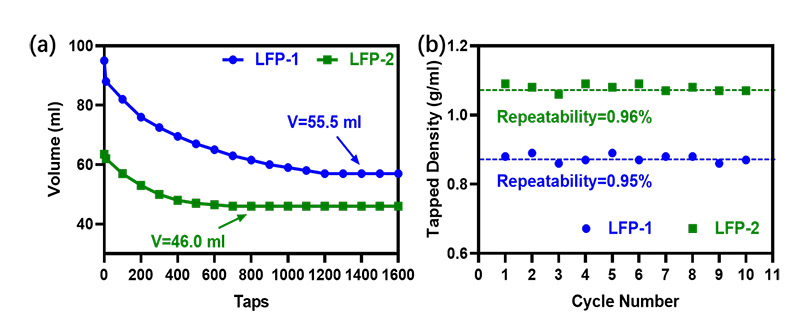

The figure 2a shows that the tapped volume of LFP-1 and LFP-2 powders is 55.5 ml and 46.0 ml, respectively. The calculation reports from the instrument display that the tapped density for LFP-1 was 0.89 (g/cm3 ) for LFP-2 was 1.08 (g/cm3 ). 10 replicates were reported in figure 2b for each sample, which confirms that the test results were highly repeatable. There are three reasons for the accurate and repeatable results:

a) the test method meets the ASTM B527-20 standard

b) the tester has a device that rotates the cylinder to minimize any possible separation of the mass during tapping

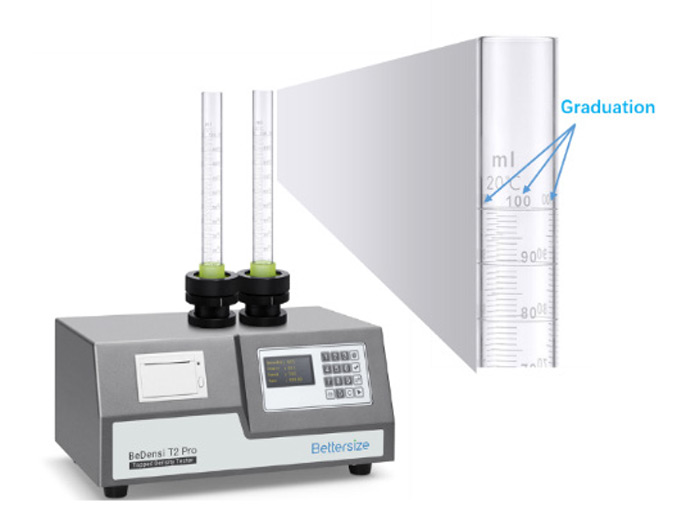

c) the cylinders are graduated and are read from 3 different angles as shown in figure 3, and then a mean value is obtained from all three readings to ascertain an average value which is used to calculate the tapped density.

Figure 2. (a) sample volume changes during tapping, (b) 10 repeat sample measurements of tapped density

Figure 3. The BeDensi T2 Pro with the easy-to-read graduated cylinders

3.2 Particle size distribution (PSD)

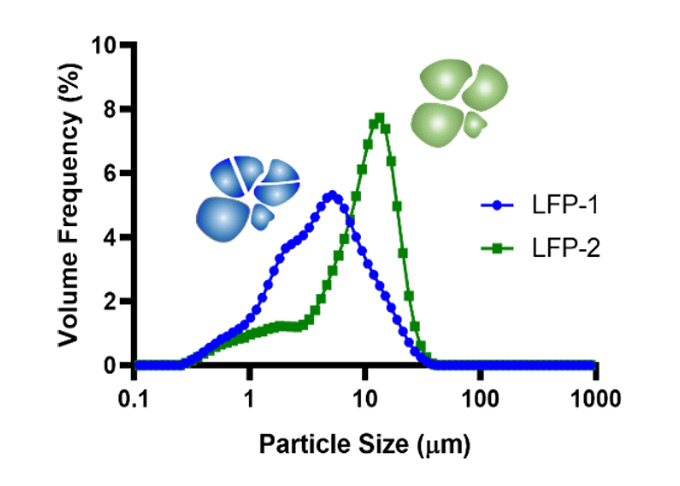

After the tapped density measurements, the particle size distributions (PSD) of the two LFP were studied. The results, as displayed in Figure 4, show that PSDs of both samples have the same range of 0.28 to 38.41μm, while the D50 for LFP-2 is 9.21μm, compared to 4.08μm for LFP-1.

Figure 4. The PSD of two samples ranging from 0.28 to 38.41

Figure 4. The PSD of two samples ranging from 0.28 to 38.41

Table 2. Theoretical and tapped density of cathode materials.

|

Sample |

Dmin (μm) |

D10 (μm) |

D50 (μm) |

D90 (μm) |

Dmax (μm) |

|

LFP-1 |

0.28 |

1.10 |

4.08 |

12.21 |

38.41 |

|

LFP-2 |

0.28 |

1.46 |

9.21 |

18.07 |

38.41 |

So, both samples have the same PSD range, while the D50 of LFP-1 is smaller than LFP-2 leading to a lower tapped density. Ying et al. reported that the smaller the average particle size, the lower the tap density is. [4] In this case, increasing the grinding time will reduce the particle size as illustrated by LFP-1 in figure 4.

The resultant effect of this reduction in size leads to a decreased density occupying a larger volume in these samples. To understand the relationship of tapped density and PSD, the tapped density tester and laser diffraction analyzer are necessary for optimizing the production process and manufacturing high-quality LIBs.

Conclusion

The reports that the BeDensi T Pro Series instrument displays confirm that the optimal tapped density has been attained by tuning particle size distribution. As one of the important properties of cathode electrode material, tapped density should be improved during the preparation process to make Li-ion batteries hold more energy in the same volume of material. Therefore, it is necessary for LIB manufacturers to employ an easy-to-use and highly efficient tapped density tester to characterize the tapped density of the electrode materials in rapid time. The BeDensi T Pro Series is ideally suitable for measuring the electrode materials for research, development stages testing to production control.

Reference

[1] El Kharbachi, A., et al. Exploits, advances and challenges benefiting beyond Li-ion battery technologies. J. Alloys Compd., 817 (2020)

[2] Yang, S., et al. High Tap Density Spherical Li[Ni0.5Mn0.3Co0.2] O2 Cathode Material Synthesized via Continuous Hydroxide Coprecipitation Method for Advanced Lithium-Ion Batteries. Int. J. Electrochem., 9 (2012).

[3] ASTEM B527-20 Standard: Test Method for Tap Density of Metal Powders and Compounds.

[4] Ying J, et al. Preparation and characterization of highdensity spherical LiNi0.8Co0.2O2 cathode material for lithium secondary batteries. J. Power Sources, 99 (2001)

About the Author

|

Perfil Liu Senior Application Engineer @ Bettersize Instruments |

|

Unlock the secrets to high-performance Lithium-ion batteries with the collection of SEVEN battery application notes. (pdf) |

|

Rate this article