Determining the Average Zeta Potential and Distribution of Battery Electrode Slurry

2023-06-25Application Note

This application note presents a study on determining the zeta potential of battery electrode slurry dispersed in NMP solvent. The experiment utilized the BeNano to measure the zeta potential of four different samples. The results showed that all samples had negative zeta potentials, indicating the presence of negative charges in the electrode materials. The zeta potential amplitudes were around 50 mV, indicating high stability. The study highlights the importance of understanding zeta potential for optimizing battery electrode production and emphasizes the reliability of the measurements.

| Product | BeNano Series |

| Industry | Battery and Energy |

| Sample | Battery Electrode Slurry |

| Measurement Type | Zeta Potential |

| Measurement Technology | Electrophoretic Light Scattering(ELS) |

Jump to a section:

Introduction

In recent years, the rapid development of the new energy industry has highlighted the significant role of lithium batteries as reusable and rechargeable batteries in various industrial applications. During the production process of lithium batteries, electrode slurry is formulated using NMP (n-methylpyrrolidone) as a dispersant. NMP serves as a solvent for PVDF during the slurry batching stage, aiding in the dispersion of the slurry to create a more uniform system. In addition, NMP acts as the primary carrier of the slurry during the coating stage, ensuring even coating on the substrate. Furthermore, during the coating and baking stages, NMP volatilizes and creates pores in the coating, resulting in a uniformly distributed porous microelectrode structure.

The stability of battery electrode materials in NMP is crucial as it directly affects the quality of electrode production. In this study, we conducted an analysis of the zeta potential of a range of slurries dispersed in NMP.

Instrumentation

The BeNano 90 Zeta nanoparticle size and zeta potential analyzer from Bettersize Instruments were utilized for the experiment. It utilizes a laser with a wavelength of 671 nm and a power output of 50 mW as its light source. To acquire the scattered light signal, an APD detector positioned at an angle of 12 degrees was employed. The phase analysis light scattering (PALS) technique was employed to accurately detect the zeta potential information of samples exhibiting low electrophoretic mobility.

Experimental

Four battery electrode materials were dispersed in NMP solvent. Due to the low dielectric constant of the organic phase NMP, the dip cell was used. Each sample was measured six times to obtain the mean and standard deviation.

Results and Discussion

|

Samples |

Zeta potential (mV) |

Standard deviation (mV) |

|

1# |

-53.43 |

3.48 |

|

2# |

-51.84 |

1.97 |

|

3# |

-50.32 |

2.46 |

|

4# |

-48.53 |

3.44 |

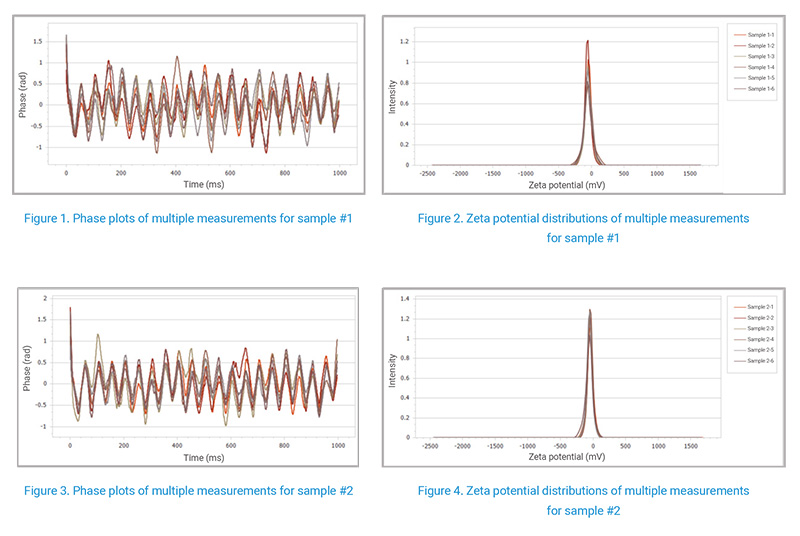

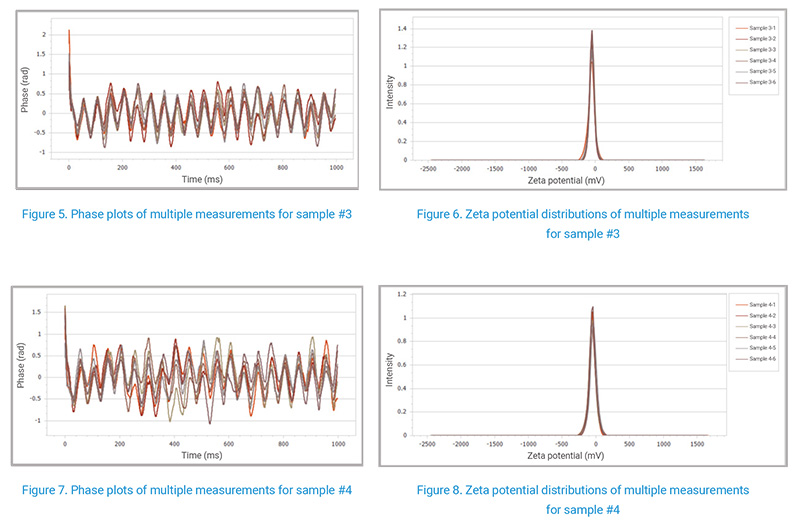

The phase plots and distribution curves of the samples in Figures 1 - 8 and the data in Table 1 show that the zeta potentials of all samples are negative, which indicates that the electrode materials carry negative charges in the NMP. The zeta potential amplitudes of all four samples are around 50 mV, and the higher zeta potential indicates the high stability of the samples. The standard deviations of multiple measurements were small, indicating good reproducibility of the measurements.

Conclusion

This application note presents a study on determining the zeta potential of battery electrode slurry dispersed in NMP solvent. The experiment utilized the BeNano 90 Zeta to measure the zeta potentials of four different samples. The results showed that all samples had negative zeta potentials, indicating the presence of negative charges in the electrode materials. The zeta potential amplitudes were around 50 mV, indicating high stability. The study highlights the importance of understanding zeta potential for optimizing battery electrode production and emphasizes the reliability of the measurements.

About the Authors

|

Zhibin Guo Application Manager @ Bettersize Instruments |

|

Dr. Ning Chief Product Officer @ Bettersize Instruments |

|

Unlock the secrets to high-performance Lithium-ion batteries with the collection of SEVEN battery application notes. (pdf) |

|

Rate this article