Application of Laser Particle Size Analyzer in Lithium Battery Cathode Materials

2021-03-23Application Note

In order to achieve high energy storage, stability and safety performance, it is necessary to strictly control the particle size distributions of lithium battery cathode materials. Therefore, it is important for battery manufacturers to measure the particle size distribution of electrode materials quickly and easily, with the Bettersizer 2600 laser particle size analyzer.

| Product | Bettersizer 2600 |

| Industry | Battery and Energy |

| Sample | Lithium Battery Cathode |

| Measurement Type | Particle size |

| Measurement Technology | Laser Diffraction |

Jump to a section:

Introduction

With the rapid development of new forms of energy especially for the vehicle industry and smart wearable devices, the research and production of cathode materials for lithium batteries has gradually attained global attention. Among the key areas of research is the development of lithium-ion battery cathode materials with a high capacity, long life cycle, high safety performance and low price. The effort in this area has become the mainstream focus of the battery industry and is in a state of rapid development. According to statistics, at the beginning of January 2021, lithium-ion batteries were at a full production schedule in the vehicle industry, and year-end orders skyrocketed. This in turn triggered a shortage of upstream high-performance raw materials, especially in the supply of cathode materials for lithium-ion batteries.

Generally, lithium-ion battery cathode materials include lithium iron phosphate, lithium cobalt oxide, lithium carbonate, and high nickel ternary materials. The particle size and size distribution of all cathode material particles directly affect the charge and discharge performance of these batteries. Therefore, it is of extreme necessity to measure the particle size distribution of lithium-ion battery cathode materials during the development and production of these batteries.

Lithium iron phosphate is a commonly used cathode material for lithium-ion batteries. Its particle size distribution determines the processing and application performance of lithium iron phosphate in lithium-ion batteries. In this application note, the Bettersizer 2600 laser particle size analyzer was used to measure the particle size distributions of 5 lithium iron phosphate samples.

Bettersizer 2600 laser particle size analyzer

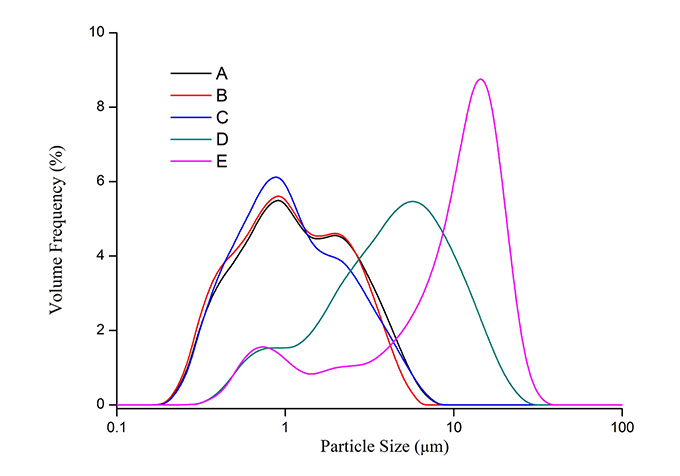

Particle size distributions of lithium iron phosphate particles

Figure 1. Particle size distribution of lithium iron phosphate particles

Typical particle size values of lithium iron phosphate particles

Table 1. Typical particle size values of lithium iron phosphate

|

Sample |

D10 (μm) |

D50 (μm) |

D90 (μm) |

|

B |

0.370 |

0.991 |

2.790 |

|

D |

0.973 |

4.228 |

11.150 |

|

A |

0.388 |

1.057 |

3.126 |

|

C |

0.387 |

0.956 |

2.970 |

|

E |

0.985 |

10.190 |

18.330 |

As shown in Figure 1, the average particle sizes of lithium iron phosphate A, B and C were much smaller than the average particle sizes of D and E. Generally, the average particle size of lithium iron phosphate has a great influence on the electrochemical characteristics of lithium-ion batteries. Small particles can increase the specific surface area of the active materials in the lithium-ion batteries and shorten the diffusion path of lithium ions in the battery, thus promoting the electrochemical reactivity of lithium-ion batteries[1].

However, if the particle size of lithium iron phosphate is too small, the particles are easy to agglomerate. This leads to a decrease of the electron conductivity and solid phase diffusion coefficient, which in turn increases the internal resistance of the lithium-ion batteries. Part of the electric current will be converted into heat energy under the influence of high internal resistance. This causes a significant amount of heat loss from lithium-ion battery, which ultimately affects the capacity and discharge performance of the battery.

According to the feedback from a well-known lithium iron phosphate manufacturer, most of the D50s of lithium iron phosphate products are in the range of 1μm-2.5μm. It has been found that the electrochemical properties are at their best in this size range because it is conducive to the effective discharge performance of lithium-ion battery to reach optimal levels. In addition, the D50s of a small amount of lithium iron phosphate particles are in the range of 3.5μm-8μm, like samples D and E, which leads to high internal resistance and poor electrochemical characteristics, thus decreasing the expected life, usable capacity, charge and discharge rates, and safety of the lithium-ion battery.

As can be seen from Table 1, the average particle sizes of lithium iron phosphate A, B and C were about 1μm, while the average particle sizes of D and E were between 4μm and 10μm. For sample E, the over-sized particles may degrade the solid phase diffusion coefficient of lithium ion in the active materials, resulting in an increased internal resistance and reduced effective charge.

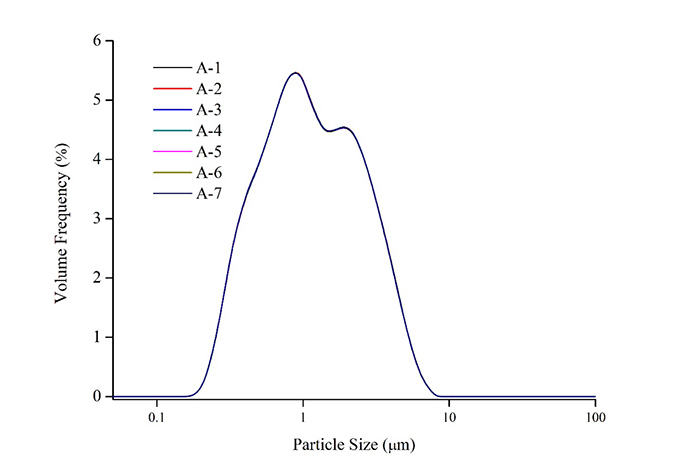

Multiple measurements of the same lithium iron phosphate sample

Figure 2. Repeatability test of sample A

It can be seen from Figure 2 that the multiple measurements of lithium iron phosphate by the Bettersizer 2600 show a good result repeatability. The values of repeatability for D10, D50 and D90 are 0.13%, 0.07% and 0.09%, respectively, which were far below the requirements of ISO 13320[2]. Therefore, using the Bettersizer 2600 to measure the particle size distribution of lithium iron phosphate has high repeatability.

Conclusion

The particle size distributions of the lithium-ion battery cathode materials are critical in affecting the performance of a battery. For a given anode material and cell size, the particle size distribution of the cathode material can be adjusted to optimize the energy and power of lithium batteries. In order to achieve high energy storage, stability and safety performance, it is necessary to strictly control the particle size distributions of lithium battery cathode materials. Therefore, it is important for battery manufacturers to be able to measure the particle size distribution of electrode materials quickly and easily, with the Bettersizer 2600 laser particle size analyzer.

Reference

[1] Battery materials for ultrafast charging and discharging, B Kang, G Ceder, Nature, 12 March 2009, vol 458.

[2] ISO 13320 (2009) Particle size analysis – Laser diffraction methods.

About the Author

|

Fangfang Zhang Application Engineer @ Bettersize Instruments |

|

Unlock the secrets to high-performance Lithium-ion batteries with the collection of SEVEN battery application notes. (pdf) |

|

Rate this article