Analysis of Graphite's Particle Size in a Convenient Way Using Laser Diffraction

2024-02-29Application Note

Graphite is commonly used in anode material manufacturing. However, the measurement of graphite particles often meets problems in the dispersion step due to their small particle size. In this note, Bettersizer ST is used, and the sample is prepared using dish detergent. The simple measurement procedure provides an approach to particle size analysis of graphite particles.

| Product | Bettersizer ST |

| Industry | Battery and Energy |

| Sample | Graphite |

| Measurement Type | Particle size |

| Measurement Technology | Laser Diffraction |

Jump to a section:

- Graphite has broken a new path

- Bettersizer ST as a practical and powerful partner

- Procedure without complication

- Conclusion

- Reference

Graphite has broken a new path

Over the last few decades, graphite, a special crystalline form of carbon commonly used in anode manufacturing, has played an increasingly important part in the soaring market for batteries. Traditionally, graphite is utilized for lubricant, brake lining, or steelmaking. Of growing importance is its application in the batteries of EVs. The layered structure of graphite allows smooth transportation of lithium-ion flow. Therefore, the cycle life is long. Besides, graphite is readily available, resulting in a low cost of ownership. In contrast to the slump of the overall car market, global EV sales have grown by over 30% in 2023.[1] Along with the double-digit growth of EV sales is the booming demand for graphite. It is predicted that the demand will be maintained due to environmental principles and the high gasoline price. For spherical graphite manufacturing, milling and classification processes will be implemented for the natural flake graphite. Proper particle size distribution of graphite ensures battery performance in terms of capacity retention, power density, or conductivity.[2]

Bettersizer ST as a practical and powerful partner

As an essential step in quality control, particle size measurement for the milled graphite will be carried out with a particle size analyzer.

Equipped with a patented Dual Lens Optical System (DLOS), the Bettersizer ST is competent for the measurement of graphite, ranging from 0.1 to 1000μm. Combined with its intelligent sample measurement under SOP, robust and durable structure design, and small footprint, the Bettersizer ST provides reliable and accurate results after legendary simple and precise measurements that save your valuable working place and measurement time towards a foothold in intense graphite production competition.

Procedure without complication

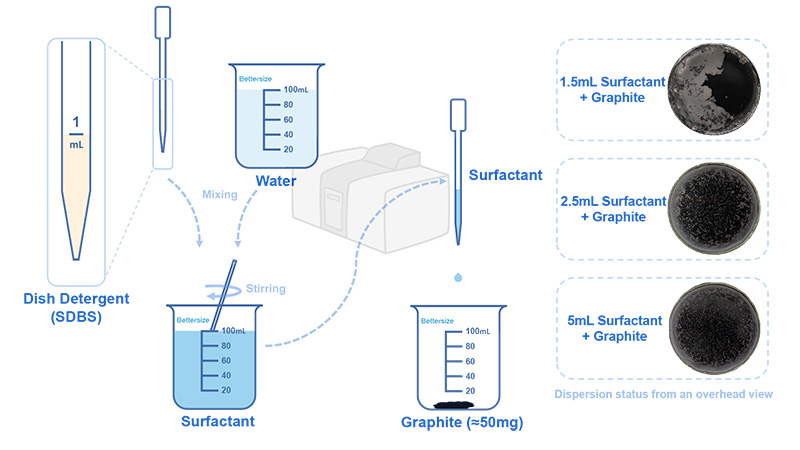

A considerable number of customers apply the Bettersizer ST to analyze graphite, whether it is measured as a raw material or a product. The high specific surface area of graphite leads to particle agglomeration. Hence, an incorrect measurement result will be caused. However, a graphite analysis with the Bettersizer ST is easily accessible. Applying a surfactant made of alkylbenzene sulfonate allows a full dispersion of fine graphite particles in water, which facilitates the measurement procedure. Alkylbenzene sulfonate is readily available and can be obtained from soap or detergent. Graphite measurement with the Bettersizer ST using prepared surfactant greatly eases your workload.

Figure 1. Preparation of the surfactant and dispersion status.

Figure 1. Preparation of the surfactant and dispersion status.

The amount of surfactant applied to the sample can greatly influence the dispersion effect of graphite. The volume ratio of alkylbenzene sulfonate to water is 1 to 100. In this study, about 50mg of graphite was sampled, and different amounts of prepared surfactant were added to the graphite sample. The measurements were carried out (rotational speed: 1200rpm; duration of ultrasonic treatment: 30s), and the results were compared, which are displayed in Table 1.

Table 1. Comparison of the measurement results after the addition of different amount of surfactant.

|

Amount of surfactant (mL) |

D10 (μm) |

D50 (μm) |

D90 (μm) |

|

2.5 |

7.372 |

16.64 |

30.54 |

|

5 |

7.351 |

16.78 |

30.68 |

The schematic above shows the preparation of the surfactant with sodium dodecyl benzene sulfonate (SDBS) from dish detergent and the dispersion effect of graphite after the addition of different amounts of surfactant. The graphite cannot be thoroughly wetted when only 1.5mL of surfactant is added, while the dispersion effect is good in the presence of 2.5mL or 5mL of surfactant. Besides, the measurement results are very close. The dispersion status is displayed from an overhead view in Fig.1. The measurement results after adding 2.5mL of surfactant shall prevail because excessive addition of surfactant may lead to foam formation during sample dispersion.

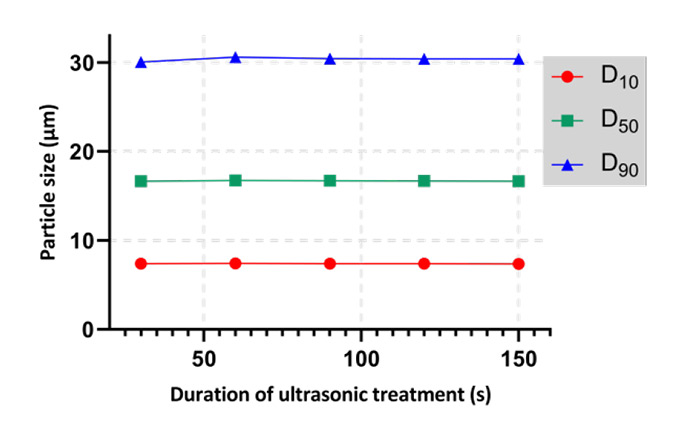

Another vital factor that affects dispersion is the duration of ultrasonic treatment. The power of the built-in ultrasonic device of the Bettersizer ST is adjustable towards optimum condition for graphite dispersion. Commercial graphite was measured with the Bettersizer ST after the treatment of surfactant according to the preparation procedure mentioned above. The power was set to 50 watts, and the sample was measured every 30 seconds. The measurement results are listed in Table 2, along with the trends of some typical values in Fig.2. The measurement results were stable after 60 seconds. Therefore, the dispersion efficiency of the Bettersizer ST with its ultrasonic device is very high. From another point of view, the fast stabilizing time shows effective dispersion supported by the surfactant. The builtin ultrasonicator provides additional assistance in case of particle agglomeration.

Table 2. Typical values with different duration of ultrasonic treatment.

|

Duration of treatment (s) |

D10 (μm) |

D50 (μm) |

D90 (μm) |

|

30 |

7.384 |

16.65 |

30.03 |

|

60 |

7.401 |

16.72 |

30.60 |

|

120 |

7.392 |

16.70 |

30.44 |

|

150 |

7.375 |

16.67 |

30.39 |

|

180 |

7.364 |

16.65 |

30.40 |

Figure 2. Trend curves of typical values with different duration of ultrasonic treatment.

Conclusion

The explosive growth of the battery industry leads to a high demand for graphite. For the acquisition of reliable and accurate measurement results in a convenient way, an excellent device is necessary — that is why the Bettersizer ST was born. Besides, the measurement condition of graphite is also significant. With the help of the Bettersizer ST, optimal conditions can be easily found due to its user-friendly settings through the software and the stable operation of the instrument.

Reference

1] Global electric car sales rose 31% in 2023 - Rho Motion. (n.d.). https://www.reuters.com/business/autostransportation/global-electric-car-sales-rose-31-2023-rhomotion-2024-01-11

[2] Maciej R., Bartosz H., Michal K., Maciej B., Dominika Z., Andrzej C. (2018). Impact of natural and synthetic graphite milling energy on lithium-ion electrode capacity and cycle life. Carbon, 145, 82-89. https://doi.org/10.1016/ j.carbon.2019.01.019

About the Author

|

Paddy Zhou Application Engineer @ Bettersize Instruments |

|

Unlock the secrets to high-performance Lithium-ion batteries with the collection of SEVEN battery application notes. (pdf) |

|

Rate this article